remski2

Members-

Posts

197 -

Joined

-

Last visited

-

Days Won

5

Content Type

Profiles

Forums

Events

Gallery

Blogs

Everything posted by remski2

-

This one ? https://www.iapdirect.com/images/T/calibrations.pdf

-

I am actually in the same boat. (subaru ej257) I've played with multiple starting fuel settings and things never got much better. Hot start in my case is great. Cold start not so.. Thus it would indicate it being fuel related. I've played with Crank Enrich Table from 20 all the way up to ~300. Seemed that there was no change. FYI.. I base my calculations on voltage drop (actual start crank), cam/crank signal sync and when the ecu logs the actual cranking rpm, to the point where it reached 400 rpm and then 1000.

-

I've been trying to tune my cold start for quite some time. Trying to shave off miliseconds with no luck. I've analized the hot start vs. cold start and seems that there is a different behavior. I do understand that cold start will always require more fuel and will take longer.. but.. When you look at the log, the hot start dwell charge starts at the same time as fuel injection thus an instant start. With cold-er engine fuel injection starts earlier and 1.1 second later the dwell kics in .. why ???

-

This is my old table.. So in my case it would kick in when IAT was above 104F. If it was a cool day the AFR's would stay pretty much the same and there would be no correction.

-

I've had the same problem.. IAT correctons would just mess my fueling.. maybe I was removing too much ? I've zero-ed out the high temp correcton and instead of that I am using IAT Ignition Trim 3D table, pulling more timing the hotter the air gets.

-

You have an IAT correction on. It is pulling fuel all the time as per your 05-27 log. Is this what you refering to? Also .. an FYI.. your fan seems to be on all the time.. and you've reach 212F on your temp..

-

-

Assuming here, you have a 3 port MAC boost solenoid.. You are running at 10% duty cycle and thats where the solenoid starts working.. (10-90% is the range) Try lowering your solenoid frequency so your range starts above 10%.

-

I'd look into grounding. You mentioned a custom Mil-spec harness. Hopefully you get a diagram so you can verify where the grounds go and if they are clean. Dont forget about the sensor grounds as well.. As far as I know they are not supposed to be grounded. You could run a voltage drop test to check or just run new separate grounds and see if anything changes. Could also be a nicked wire..

-

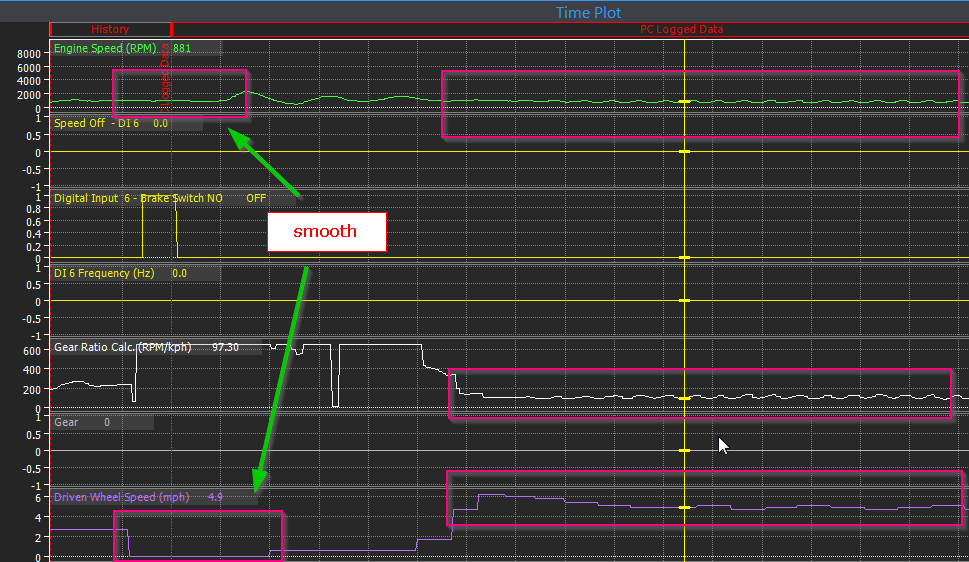

You are showing Driven Wheel Speed while at idle. There is a place where there is no Driven Wheel Speed and your idle looks better. Your Gear Ratio Calc indicates that you are in gear and moving. Is the ECU getting confused ?

-

Get the car to normal operating temperature and adjust your main fuel table so the AFRs are 14 - 14.7 during idle. (make sure all fuel corrections are done) F12 will show you if there are any trims that are on. Then smooth the fuel table back around that area. Next day start the engine and now you can play with your Warm Up Enrichment. At start I have my engine running 13.8 - 14. Adjust your warm up enrichment so it reaches your idle AFRs, once ECT reaches your operating temps. (158 F in your case) HP Academy and Evans Performance Academy are a great resource if you want to learn more.

-

Do you have lambda sensor? There is no AFR info in your log.. so it could be fueling.

-

Just browsed throught your thread.. Did you sort the valve clearance out ? Also .. since this seems cam related.. I am sure you've checked the buckets for abnormal wear... but have a read anyways.. Cossie cams could come from the same casting plant.. https://forums.nasioc.com/forums/showthread.php?t=2642831 I had a set of GSC cams with minor scoring on the buckets. Also did you do the cam break in procedure ?

-

I have a Motec PDM starting the engine. All the logic is configured in the PDM. Since I have auto-start configured, all the ECU is providing is RPM via can back to the PDM. (so it will stop cranking once a 400 rpm is reached) Same button is used for STOP and ECU is configured to accept Anti-theft CAN message to cut spark and fuel.

-

Your input units are volts and output units psi (bar) ?

-

Have you checked your cal table associated with it ?

-

Just throwing it out there.. I did have a set of fake NGK plugs off Amazon... I didnt have any missfires but it seemed to knock a bit too much under low ignition.. Also have you tried increasing dwell at that rpm ?

-

Not sure if you saw that lean spot starting at 4K and ending around 4.5K.. Maybe it wants more fuel at that rpm.. or maybe an injector/fueling issue ? I see the pw doesnt change. On a 2nd note.. your dwell time seems to be jumping a lot between 1.2 and 2.9ms.. (~3k rpm range)

-

Well.. one thing comes to mind if it was running correctly and seems lean besides the fuel is that you have a leak in your exhaust allowing air in and messing up your AFRs. 2nd thing I noticed is that your fuel table is stays flat during your run. From 4900 to 6600 its pretty much flat at 51.5 - 52. I'd think it should increase as 4000 to 4700 there is a jump from 41 to 50. You injecting anything like meth ?

-

Are you sure you are tuned correctly. New sensor reading incorrectly ? Looking at the log you are at 29psi boost but AFRs are ~17.

-

Anything connected to your outputs thats not using a relay ? IE: engine fan comes to mind since you mentioned tripping when its hot.

-

Well.. Constant 10 would be very rich and that would mean the injectors are not shutting off. Look at your Overrun Deactivation Table to see at what RPM the injectors come back on .. seems like 1200 to me.. If you think the sensor is failing .. have you compared Lambada in your logs ?

-

For ECT/Knock concerns you do have a "ECT Ign Trim 3D table" where you can add or substract timing based on ECT. Oh.. nvm on the idle ignition table.. it was rolled up and I couldnt see the rest.. all good there. As for ALS and LC I havent gotten to that on my ecu yet so I wont comment.

-

Change RPM limit to igntion as mentioned above but change your End Cut to around 100% instead of 60%. (cut will be very abrupt and you might get a pop and a bang) Few other things... Also noticed that your Warm up enrichment table is always on. Ignition Idle table is not doing anything.. Question about the Knock table.. Why did you choose ECT as one of the axis.... any benefits ?

-

Right off the bat I see your Short Pulse Width Adder is incorrect for 1050x ID's. Apparently Link used GM characterization data break points so use that.