Sutkale

-

Posts

158 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by Sutkale

-

-

Hey.

Maybe its time to update my Vipec i88 to Link G4+ Thunder. I suppose looms A & B from Vipec i88 fits straight to Thunder. C&D looms needed? Anything else to consider?

-

-

Hi Sutkale,

great result after so much heart ache for you.

Sometimes things are just what they are, I have had issues with trigger wheels because of the metal they were made from etc.

It is very frustrating at times and almost always leads the owner,mechanic or tuner being suspect about the ECU.

Then when the ECU is tested and gets the thumbs up, it's OK., the circle of despair starts again.

I have had trigger errors from loose timing chains and belts, trigger discs just touching pick up sensors , air gap issues you name it.

Well done anyway, you have nailed it, with the advice of Simon recommending a tooth count change.

Regards

Dave.

Yup, this was really a pain in the arse..

-

Got this thing working, no trigger issues with 36-1 wheel....

This makes me wonder why it didn´t work with 60-2, too much load on the micro / trigger circuit?

This makes me wonder why it didn´t work with 60-2, too much load on the micro / trigger circuit? -

It´s kinda amazing folks having so much issues with Racepak dashes. I was about to purchase one and tried to ask some details from manufacturer directly and from Racepak forum. No one bothered to answer and I didn´t purchase one. Happy with that decision.

-

Hi Sutkale,

Keep us posted please.

Regards

Dave.

I will. I will change the trigger wheel to 36-1 first and take new measurements. Try to take some video / photos and post over here too from the measurement.

-

Had a possibility to scope the crank signal with quality digital & analogue scope. There was absolutely nothing wrong with the signal when the problem / trigger error occurs. Had no time to scope the cam signal, but will do that within few days. Hopefully there´s nothing wrong with the trigger circuit in the ECU board..

-

hi mapper

well let put it this way,my point here is not to add more units (boxes) but to reduce the units.

i said that there are other ways of doing it like adding expander but what i found is that i had guys that didn`t wanted to go for that route.

i could go with a racepak instead of a dash 2 pro and put all the data on the racepak but still was not my point as you are adding more units.

for some application 25 channels are more than enough but what we do if you have a drag high application with a V8 twin turbo and chasing a misfire down the track??

never used an lc2 as i have a very bad taste of innovate from my past experience and besides that innovate claim that the lowest is can go is .5 lambda.

on methanol application that is not enough.

So the point of all this is that while a brand of ECU have some of the features i mentioned up here and cost much lot than our units,people are still buying them so why not LINK can have a unit that come close or surpasses them?

regards

jason

Hi Jason,

Sorry for off-topic, you said going 0.5 lambda with metanol. That sounds quite impossible since lambda 1 is stoich with every fuel used. Just out of quriosity..? Or are converting from (methanol) AFR to lambda?

-

Hi Sutkale,

I cant really remember it has been some time since I have used a 500 R, but I am sure that the use of resistored plugs is not advisable.

Are any of the output wires from the CDI to the coils near the trigger wiring,

or is your tuning usb cable near the CDI unit or wiring.

Regards

Dave.

Hi Dave,

CDI output wires are at closest to cam and crank wires app. 20-30 cm, so not so close I would say. Tuning cable and ECU are in the cockpit and CDI unit in the engine compartment, thus pretty far away from each other.

This ECU and laptop break up gave me an idea to put ferrite beads around the power cables to see what type of an effect this has and wheter it would be of a help to trigger issues. Furthermore, I will put some aluminium tape around the trigger cables to increase shielding against EMI / RF. I also noticed the tuning cable is without ferrite bead at the cable end that is very usual set up with USB cables.

So lets see what will be the result.

-

Hi Sutkale,

losing communication from ECU to LAPTOP is normally a good indication you are either,

1. Running non resistored plugs

2. Fouled or partially fouled sparkplugs.

3. Noise from alternator or ignition sources , referring to HT noise, ignition triggering signals especially if using a CDI unit.

Regards

Dave.

Thanks Dave for the answer. I have got resistor plugs, changing of plugs doesn´t have any difference. Autronic´s CDI cables are twisted even though manufacturer states this is not neseccary. Alternator might be a source for issues, maybe for trigger issues also?

-

Regarding this issue, I will install 36-1 crank trigger wheel and have a try with it. Cannot find suitable 24 or 12 teeth wheel that would fit auxilliary drive belt pulley. Howerver, I managed to get little progression with this by changing the position of cam wheel, by enabling occassional trigger error free runs on a neutral gear revving that wasn´t the case before.

Maybe a bit off topic, but have anyone else encountered any issues on a occasion where you try to capture a scope log from a trigger on a high revs and at the same time lap top disconnects? This was repeatable many times.

-

-

Do you need to retain the 60-2 or could this be changed to a lower tooth count like 12 or 24 teeth?

It´s not an absolute neseccity, I could maybe get a billet crank pulley wheel with teeth incorporeted on to it.

-

Hi Sutkale,

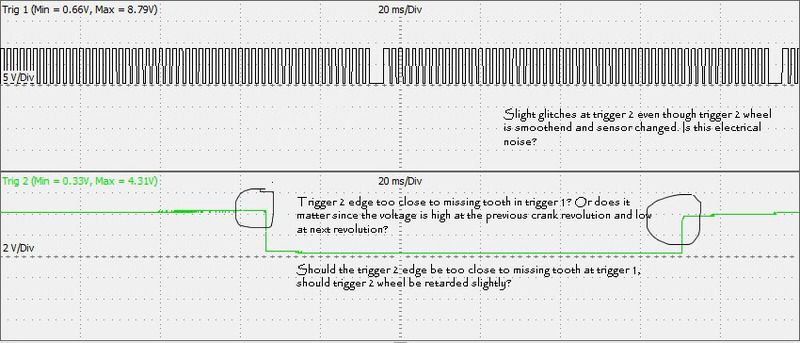

Is your trigger 2 signal clean now or does it still have glitches.

Also, I can't remember now but you only have 1 tooth on the cam sensor and is 60-2 at the crank.

Any chance of timing belt deflection via harmonics is causing any trigger error on 2.

Is the trigger 1 wheel on the harmonic balancer, if could the keyway be worn and the balancer and trigger wheel have movement.

Trigger 2 glitch could also be damaged sensor or corroded or wet connections or poor termination at pins etc.

Trigger errors occur on acceleration hard, definitely not when you take your foot off the accelerator pedal.

Do you have a lightened flywheel.

Are all cylinders definitely running 100 %, carry out compression test, have you checked the ignition timing on each individual cylinder.

Is your ignition delay value set correctly so there is no timing drift at any given rpm.

If you run the engine connected to your laptop and PRESS F12 RUN TIME values, go to TRIGGERS and LIMITS, free rev the engine and watch the TRIGGER STATUS on trigger 1 and 2, make sure they both stay GREEN and say yes.

Just curious as to whether or not it changes even slightly when trigger error occurs.

Does the tacho also play up and go crazy when the trigger errors occur, does it try to replicate the 50 - 60 K RPM.

Just a few more things to consider.

Yup, lot´s of things to consider of. I´ll start with re-routing trig 1 and 2 and see if it has any effect.

-

Got new engine running finally. However, this s***t hasn´t gone anywhere..

Changing CDI connector and pins at CDI box end did not help that I thougt would be the final solution since got some loose pins over there dropping cylinder #3 from the game occasionally. So clean trigger at start and revving cleanly until 7000 rpm and then issues occurring espeacially when revs accelerate very fast. When revs don´t come in that hard, at higger gears, the run is usually without trigger issues. Should the ecu see trigger error, it usually causes 15-20 error causing rev calculator to see 15.000 - 65.000 rev spikes and and got rev limiter activated.

Changing CDI connector and pins at CDI box end did not help that I thougt would be the final solution since got some loose pins over there dropping cylinder #3 from the game occasionally. So clean trigger at start and revving cleanly until 7000 rpm and then issues occurring espeacially when revs accelerate very fast. When revs don´t come in that hard, at higger gears, the run is usually without trigger issues. Should the ecu see trigger error, it usually causes 15-20 error causing rev calculator to see 15.000 - 65.000 rev spikes and and got rev limiter activated.Gotta do more some test driving within next days and see if I get any hint what could be causing this. For some reason I think this is more related to some other issue than directly to crank and cam sensors or their wireing since start and low rev running is clean.

-

This is what I understand what you should do in this case.

If you reduce the master fuel number then: 10/7 = 1.42857 then multiply this number with your fuel table numbers.

If you round the number up it's 43% increase of your fuel table numbers.

Thanks!

-

Guys,

Maybe I should know that, but don´t. If you reduce the master fuel number from 10 to 7, should the fuel table number be increased by 30 % in order to get the same fueling than with 10ms master fuel?

-

Wouldn´t it be a good idea to put some info upon this to the main site as folks wouldn´t get confused from this brand "merger" and be able to download the latest firmware updates from link site?

-

Cool. Good find. This shows (again) that one can not trust a part even tho its new and should not propose a problem on paper. Is this one of the Aeromotive filters?

In lieu of this, Anyone that can recomend me a GOOD aftermarket filter?

Well, I've been using Bosch 4 micron paper inline filter for years without issues, and only on E85.

-

Yes, iVTS files works properly in G4+ software, I tried it. I actually started to like the Link software after playing a bit with it...

I think it would be could idea to update Vi-Pec site also with 5.4 firmware if some bugs are fixed from the older version.

-

Dave, is there really firmware # 5.4? The download site states the following "iVTS 5.3.1.2395" as the newest one.

EDIT: It seems there´s "PCLink G4+ V5.4.0.2399 (09-04-15) ENG-JPN" available to Link G4+ though.

You guys freezing down the development of Vi-Pec ECU´s? :roll:

EDIT2: Haven´t tried G4+ software in i88, but I suppose it works?

EDIT3: Yes it does: http://www.linkecu.com/support/download ... nformation

-

A bit off topic and not really a bug, but modelled fuel option does not support injectors over 3000cc. Not an issue for most of folks but those who´re using lawn cutter size engines, this might be an issue...

-

Is your ABS sensor putting sini wave or square wave as output? Mine is putting sini wave and it is transformed to square wave to make the ECU understand the signal.

-

Good day,

Just out of curiosity would you be willing to share any fuel pressure data? For example, what differential pressure are you working with and do you have an estimate of what peak fuel pressure do you expect the injectors to see? In addition, what's the displacement of your engine?

Hello,

Base fuel pressure is 400kpa absolute and running 1:1 fuel pressure regulator. Max boost would be around 450kpa absolute, so we're seeing 850kpa peak fuel pressure at 450kpa boost? Engine displacement is 1998cc.

Updating to Thunder

in G4+

Posted · Edited by Sutkale

Sounds like an easy upgrade, thanks Dave!