Sutkale

-

Posts

158 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by Sutkale

-

-

The traction control is a dedicated function that is able to use an ignition or fuel cut in combination with an ignition retard to achieve the desired amount of slip. The system is PID tunable, so should be able to work in almost any situation. There is also optional dual slip target tables to allow for a change in the amount of slip at the flick of a button

The new Gear Shift control can work with a normal H pattern clutch system through to a sequential system using a strain lever and gearbox position feedback.

We've used the features a fair bit but are interested in hearing feedback from people who use the new features

Scott

Would be nice to try this on icy road, but have no engine under the hood currently..

-

It seems we have got a new firmware with main features like traction control and gear shift. Is traction control so called "full blown" traction control? What about gear shift? -> a gear cut property for those using convetional clutch based gear shift?

Looks damn good now..

Waiting for the spring and new engine.

Waiting for the spring and new engine.

-

Hi Sutkale,

have a great holiday, I will look for your PCL file, I have hundreds and hundreds of PCL files.

I just have to remember what I have saved it as.

Just to clarify, you wish to run Sequential / Staged Multi Fuel (METHANOL) eventually correct.

As the multi fuel Equation will have a big impact on the importance of the PCL setup.

Do you remember what you called your PCL, will just help me find it.

IS IT VOLVO - BENSA

Regards

Dave.

Hi DAve,

Yes that´s it...

But that is for my gasoline set up, but doesn´t change things in this respect.

But that is for my gasoline set up, but doesn´t change things in this respect. Yes, sequential / staged modelled fuel equation.

-

Hi Sutkale,

can you post your PCL file and I will help set it up , take screen shots and post on the forum with explanations .

This way everyone can learn.

It is easier for me to do in this fashion.

Regards

Dave.

I am currently on holiday trip, can do later this week.

Edit: actually I emailed that to you on late October..?

-

Engine is currently in pieces at the garage floor, so it is time to do some virtual tuning..

Has anyone have time to think how the modelled fuel equation works with staged injection? I particularly have paid attention to injector set up and do not know how to put the settings in the following situation; under injector set up one should put down the true flow rates of the injectors at given pressure (3.0 bar I assume). If you are running staged injection, is the injector flow rate number a total number of injector flow? Given you have primaries 1200 cc and secondaries 2300cc, is the flow rate number 3500cc (each cylinder is sprayed with 1200cc + 2300cc injector)? Should the secondaries start to spray when TPS exceed 30 %, is the ECU capable of calculate the right opening time when only 1200cc´s are spraying when TPS is under 30 %.

One thing that I noticed is that the software do not accept bigger injectors than 3000cc. In that case and provided that total flow of injectors is more than 3000cc, does the modelled fuel equation work at all? I am gonna play with methanol so big injectors are needed in 4 cyl engine.

-

Hi,

I received a reply from Andre Simon HPA and he informed me that the original 5.2.2 webinar file got corrupted.

They have redone the 5.2.2 Webinar and hope to have it up on the HPA http://www.learntotune.com site in the next coupe of weeks.

Regards

Dave.

Okay, good news..

-

Okay, waiting for that..

The webinar is now listed on HPA's website, but it is not working though...

-

Okay, waiting for that..

-

Will it be available later on for those who missed this? Wasn´t wake up at 5.20 AM on MONDAY..

-

Is your sensor at your gearbox/before the diff or at the wheels? As Simon mentioned, what version of the firmware are you running? I haven't had a chance to go out and upgrade it/test it yet.

Running i88 ecu and sensor is located at wheels.

-

Not the latest firmware, but i updated it not to long ago, but will update to latest and try again. Please note the sensor is on the output shaft and not the wheel (hence the high number)?

It has 44 teeth so by my maths that's not many revs per second to get to the 500hz max?

Cheers.

This intrests me too since I am running 42 teeth ABS and I loose the speed at app. 250 kph. Rather annoying if running gear by boost and gear indicator jumps to 1st gear where boost setting is different than in 5th gear.

-

Guys,

One thing (beside the numerous other ones) came to my mind also. What does the fuel table numbers represent in this new mode? Are they still multiplayers like in the tradional fuel mode? Is there any calculation method available for the public or is this proprieatary info? This would make me understand better how the ECU determines the actual injector pulsewidth in real conditions.

-

Hi ,

the fuel temp input is very important, however not a necessity, from memory.

Quickly looking at the PCL file you sent me the sec/pri ratio calculation you have made is correct, however are you 100% sure these are the true flow rates for these injectors at 3 bar.

What are the actual injectors, brand etc,

DEAD TIMES ETC are very very important in this type of setup.

You also mention about the warm up being fairly good until 40 deg C, you also state that you are using the Charge Estimate table for your warm up and it is setup for 100 % biasing to the ECT.

However I see the Charge Estimate table set up as MGP vs RPM, no reference to ECT at all.

Your WARM UP ENRICHMENT table is at 0, no influence, but is on.

IAT correction is turned off, no influence.

You are running what I would consider very strange Injector timing angles especially at 500 rpm to 1000 rpm zones.

400 deg at 500 rpm and then 290 deg at 1000 rpm.

There will be some wild interpolation from 500 to 1000 rpm as far as injection timing goes, not to say this isn't correct for your setup, however on a new setup I would be going for more consistent and basic (realistic default) numbers in the table until you can tune these value/table correctly on the dyno.

I have only had a ten minute look so far and the above are my observations so far.

Regards

Dave.

Hi Dave,

I know one should know the true flow rates of the injectors when using modelled fueling equation. These are some Bosch EV14 injectors purchased from Fiveomotorsports. I will get these measured and get the actual flow rates and dead times later on.

Regarding the Charge Temp Approximation, the axis setup is locked to MGP, at least on my case..? Are you Dave able change it in your software?

The injector timing is not subject to interpolation on idle, since the idle rpm is around 1200 and the timing is 290 from 1000 to 1500 rmps. However, I will have a closer thought upon that.

I noticed that short pulse width adder table had 0,406 as default value and zeroing that actually put the lambda close to 1 at idle when I did a short test.

This was only a short test and will take this mode on use whit the new set up. Very interesting indeed...

-

Put this into a real world test. The engine started nicely at 0 celsius ambient and had rather good warm up with 0,87- 0,9 lambda at idle. Once engine reached about 40 degrees, lambda dropped to 0,78 - 0,82. Pretty much nothing helped the fueling to reach 1,0 lambda at idle. Charge temp was 100 % relying on ECT. Every set up should be right but the fuel temperature sensor is missing and I cannot verify the true flow rates of the injectors. Maybe the lack of fuel temp sensor causes this? Only changing the size of injectors under injector set up (2200 - 1200) had an effect on fueling causing even more fatter fueling..

Funny that the injector actual PW stayed almost steady at 2,5ms and nothing at the setups made this change (exept the change in injector size). I know the engine needs 2,0 ms to reach lambda 1 at gasoline.

Just training with this nothing serious yet.

-

Hi Sutkale,

Very good question,

can you please post your PCL file you are currently playing with 5.2.2

It makes things a little quicker.

So you have selected sequential/ staged as injection mode and modelled as your fuel equation mode is this correct.

If you post your PCL will take screen shots and explain the best I can.

I am under the impression that the injector flow @ rated pressure is per injector, especially considering you are running staged injection.

So this value should be the true given flow rate of a single injector at the used fuel pressure, EG from memory an ID 1000 is actually 1015 cc at 3 bar.

Regards

Dave.

Hi Dave,

Yes, modelled is the fuel equation and fuel mode sequential / staged. Haven´t run it in real life yet, just preparing it currently.

It seems I´ve got a bad deal with the forum since it does not let me attach files "The extension pclr is not allowed" this time.. :twisted: I´ll put some mail to you.

EDIT: file is in your email Dave!

-

Hi,

I began to play a bit with the new 5.2.2 firmware and with the modelled fuel equation mode. I am running sequential / staged fuel mode and the primary injector are rated 1200cc @ 3 bar and secondary injectors are 1000cc @ 3 bar. Secondary injectors starts to inject fuel on a condition when TP exceeds 30%.

Now a few question: under the injector set up you have to put in the injector flow at rated pressure. If you use staged injection, is this the total flow of injectors, 2200cc in my case? The ecu is then able to calculate the required fuel also at the lower load when only the primary injectors are on use (i.e. under 30% in my case)? And does the injector rated fuel pressure mean measured pressure or absolute pressure? I suppose measured pressure as the injector manufacturers states the pressure, "3 BAR" -> 400 kpa in absolute.

-

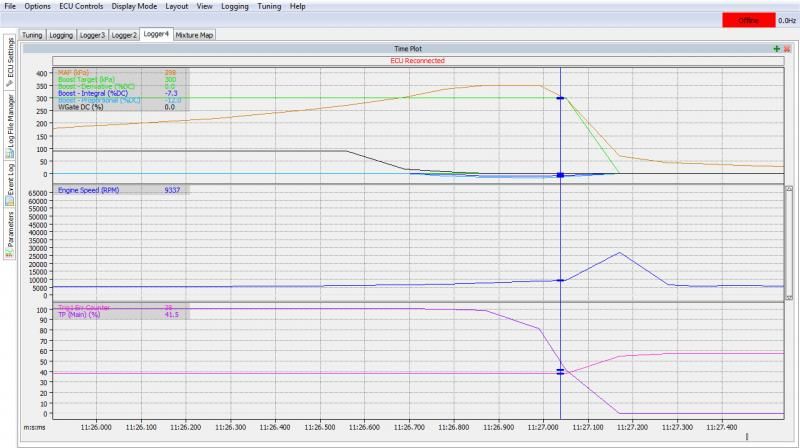

Okay. I put the car on winter rest and gonna do some engine work during the winter. Haven´t found any actual reason for the trigger error issue but found out something that might be interesting - ECU actually triggers the trigger error when I am holding off the throttle. The exhaust bang comes so quick at high rpms that its almost impossible to recognize whether it will be triggered at 100% TPS or when I hold off the bedal. Maybe this explains the situation far better (see the trigger error counter and TP % below):

Any thoughts?

-

I spotted this Electronz´s "führers" interview where he is talking about Race Technology Dashes and Link G4+

Have anyone used this with success in i or V-series ecus? Pricing seems to be reasonable in basic version but options increases the price though.

-

Rather good drive at 1 mile event with moderate boost. Only 11 trigger errors between gear shifts from 1st to 2nd. No errors during the rest of the run.

-

A bit offtopic, but where did you get the Link CAN that works with IQ?

-

Simon and DAve,

Actually there´s a bang in exhaust and engine hits the "rev limiter" when trigger error occurs (usually 9300 - 9400 rpms). For example running between 7000 - 9000 rpms on load engine runs fine and no trigger error occurs - could the timing still deviate from the set timing if there is no errors counting? Anyway gonna have rev limiter at 9000 to make things safe if the situations is that trigger error free runs really do not shift timing?

Haven´t checked timing with the timing light after having got the right basic timing.

Found out that Trigger 2 cam wheel surface is a bit coarse since it is made from stock cam wheel and there´s some scratches from grinding device. That probably results small glitches to signal.

Guys could you please clarify the basics of trigger error function? Is there an error in signal, error in sync between cam and crank signals, tooth / teeth are missing or misfire?. It seems that trigger error as such is a bit misleading if the actual reason for trigger error could be a result for many things. Any chance to develop some sort of fault tracing mechanism for this type of issues? It is obvious ECU sees something, but what it is actually seeing in these type of cases. Tracing these type of issues can sometimes be like finding a needle from the hayrick.. :twisted:

-

Not really help from signal conversion... :evil:

Also disconneted factory ECU and no effect at all, so it can´t be attributed to the sharing of signal.

One thing that confuses me, is that according to the logger, both trigger signals are present even though the error occurs. Does this mean the ECU looses sync of tooth / teeth but signal is still present (as I assume)?

However, the engine revs nicely up to 9200 - 9400 rpms on load so I can participate 1 mile speed event on coming weekend.

-

Okay, did install the reluctor interface to trigger 1 wire and things looking good - at least on idle. Engine starts instantly and hard even on E85 and outside temperature 13 degrees celcius. Haven´t tested on high rpm but looks good so far. For some reason this does not really care whether the trigger edge is falling or rising, works on both.

It seems that trigger 1 is not dropping below 0 volts, should it?

-

It is worth a try. It can often be hard to keep both systems happy when sharing signals.

A scope image at the point a trigger error occurs would help alot but is not an easy thing to get.

Yup, tried numerous times, but not being succesfull so far... :twisted:

Anyway, getting much more stable runs on 1st and 2nd gear now with shielded cable installed all the way from the sensor. Only few trigger errors when rmps exceeds app. 9300.

Spotted pretty much an identical issue from Haltech forum; slow acceleration, no symptoms but issues occur when rpm ramp rate is faster:

Modelled fuel equation

in Vi-PEC i Series

Posted

I forgot the whole thing. So is there any chance to get the modelled fuel equation into operation if you´re running staged injection and the injector size exceeds 3000cc in total (modelled fuel equation accepts 3000cc as maximum)? In my case running primaries as 1200cc and secondaries 2300cc, resulting 3500cc. Running E85 and methanol in app. 1000 horses 4 cyl engine. Running on E85 smaller injectors would do, but on straight methanol even 3500cc´s are on their limits.