-

Posts

13 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by nate42

-

-

OK, thanks for the input Adam!

Here is a log after AP and TB calibration. Map also attached, work in progress as we need to solve this issue first before we can go back to dyno. -

Has time to look into this more. Calibration goes without problems. Did it multiple times, didn't solve the problem. Found that someone had problems if 5V output wonders, but that is rock solid. Now I've found a french thread that underlined a problem with this throttle body. Apparently (what I understood with translator) it can't take vibration very good. On OEM ECU there was also occasional stalls on idle. So I think I'll try next with new TB.

http://sevener.fr/viewtopic.php?t=17670

Throttle body in question.

-

I've got this weard problem on Link Fury on Ford Duratec HE 2.0 engine. Car starts and works fine, but suddenly Aux 9/10 voltage starts to taper to zero and causes Fault 73 and 77. What could be the cause for this. Also noticed that alternator is not charging, could this be related. Voltage was slowly dropping and was at 11.92V when this happened. Attached is the log file where you can see the problem appears at 3min mark, look Aux 9/10 Supply (V).

Any suggestions on how to start solving this problem? Anyone had similar issues and what could cause all this. Could this be calibration related problem?

-

https://gaugeart.com/product/gaugeart-analog-to-can-converter/

Found it !!! Probably two of these and I got my input needs covered

-

Was there also some other module that had 6 analog 0-5V inputs and 2 thermocouple inputs? I remember seeing that, but can't find the manufacturer, they also made small CAN displays. It was also posible to daisy chain these modules. I'm just looking for a best way to add inputs through CAN to my Vi-Pec ECU. If somebody knows the product let me know, I'm getting crazy as I can't find it

-

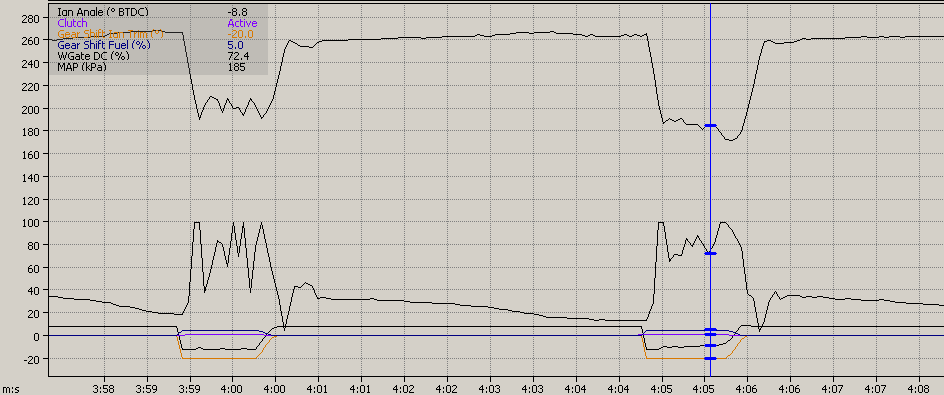

What controls the wastegate during the shift? Would increasing the amount of sparks during the shift raise the boost?

-

Was brave enough to try some flat shifts. It just works!! :shock:

Boost drops a bit too much during the shift, can this be avoided somehow? Here is a graph of my 3-4-5 shifts and my current settings.

Gear control data during shifts

My settings

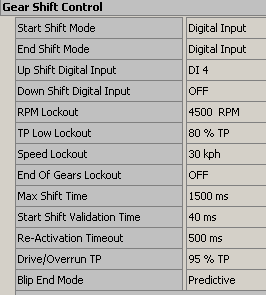

I have same settings for all gears:

Cut for ignition: 90%

Torque introduction time: 200ms

Ignition trim: -20 degrees

Fuel trim: 5%

-

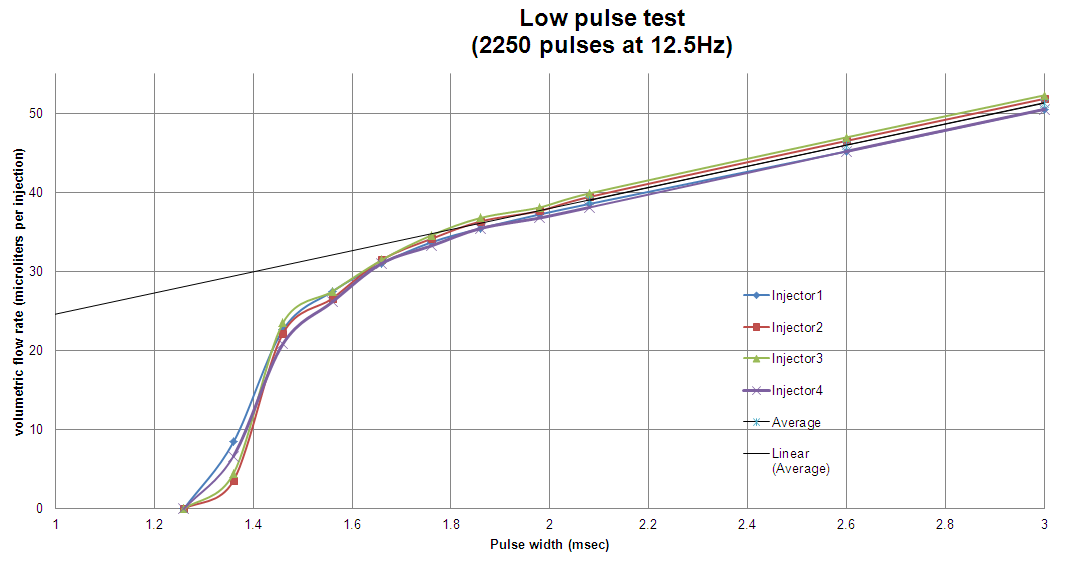

Got some injector data measured with an injector bench I bought from Alibaba

It can only measure in increments of 0.1msec. All was done with 3bar and 14V. Machine is not very accurate ie 1.5msec is 1.56msec when you measure the pulse with oscilloscope, this was taken to account when collecting data.

Measurement data in graph

Few questions.

-Is my "Min Effective Pulse Width" now 1.36ms that was the first point where at least something came out from the injectors or should I take a first value where all injectors perform roughly the same (1.46ms)?

Don't use range before 1.55ms, above that it can be corrected to linear

-Is this also my "Injector Dead Time Table" value at 14V

No, that is a different thing

-How do I calculate the msec values to "Injector Short Pulse Width Adder Table"?

Figure out how many ms you need to have the injector open to be on the linear line. So open time plus added time should result the amount of flow of the linear line.

All input is welcome!

-

Good news, Ethanol sensor works! In the end I had focked with the wiring and connected to wrong pin at the ECU :shock: :oops:

This was the reason for the ESP error light also.

Updated to latest firmware and experimented little with Modelled Multifuel. Looks quite complicated. I had trouble to get it idle it was running that rich, ran out of adjustment on fuel table. Have to give it another try with more time (double check injector data) and better weather. Too much snow here to make any runs, so have to do other work to the car and get back to the software when spring comes.

-

Hi,

DI6 (pin 40) should work fine for an ethanol content sensor. There has been a problem found lately with getting the ethanol sensor to read. Use the following work around until the next firmware release:

1. Set DI 6 to GP Input.

2. Set the Active Edge to Falling.

3. Store the base-map to the ECU (F4 key) and cycle the power to the ECU.

4. Reconnect to the ECU in iVTS.

5. Set DI 6 to Ethanol Sensor.

6. As you are using the continental sensor set the Pullup resistor to ON.

I do not know the knock frequency of the 1.8T engine. However there is a calculation you can use to determine it:

Knock Resonant Frequency (Khz) = 1800/(3.14 * piston diameter in mm)

I believe the piston diameter on the 1.8T engine is 80.965mm. This would give a knock frequency of 7.08 kHz.

In my experience the calculation has been accurate.

For the MAF reading, unfortunately Cal tables 1 to 3 have a fixed amount of columns.

The Torque management is currently only used for specific plugin ECUs: a jetski plug-in and the Nissan 350Z plug-in. The help file does contain some information on torque management, but other applications are not supported (or tested) by us. On other vehicles the VW/Audi 1.8T plugin ECU has been installed on I have not heard of any changes needed to manage the ESP light. Maybe try disconnecting your battery for a while to try and reset this.

Scott

Will test by your instructions and report how it goes. What firmware is recommended to run flex fuel on this plug in ECU?

Ok I'll just forget the MAF for now, kind of relief as they don't last very long when used on the limit.

Will read the fault codes from the ESP and report. Could be something non ECU related also :oops:

-Nate

-

Hi nate42,

I have remote tuned and helped a customer with the TT plug in on his Jetta which has been stroked to 2.2 litres , big turbo all the fruit.

I will see if I can get Simon or Scott to answer your question as we have a flex fuel sensor on the Jetta but we haven't tried to fill with E85 or anything as yet.

You do not have to sacrifice any functions as there are also extra pins available to use.

I will post this up for you.

Regards

Dave.

Thanks Dave,

I'm also building 1.8T stroker with big port head and all goodies. I want to make everything perfect on it so not in hurry, so for now I have to live with this ~400hp setup. I the words (rough translation) of Finnish rally legend Juha Kankkunen "You can live with under 500hp but it's subsisting"

ECU was surprisingly easy to set up on 1.8T even idles quite nicely out from the box with modified (mesh removed) Bosch EV 1300cc/min injectors

-

Hi everybody!

New to this forum and been experimenting with plug in ECU on my Audi TT and quite impressed so far

In short the setup of the car is:

-Stock APX block and head, just stronger rods

-EFR 6758 turbo with needed pipe work

-Big injectors, inline fuel pump, etc bits you need to make work

Few questions:

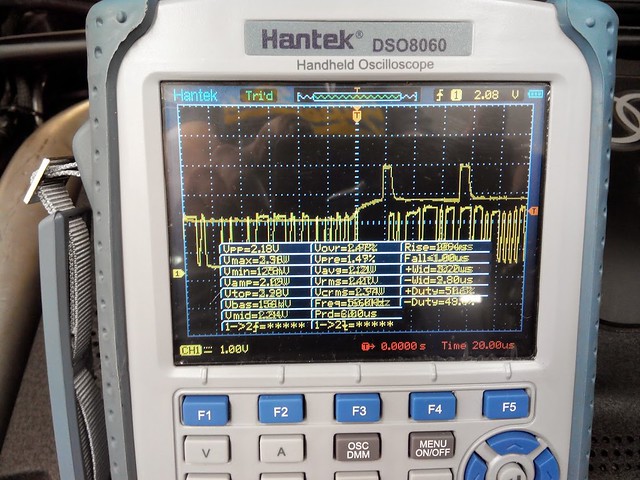

- I've plugged the Continental Ethanol sensor to DI6 (sacrificed the A/C request signal) pin 40. Scoped between the pin and earth and something is going on, so there is a signal.

Scoop showing the waveform

I've set the resistor on from the ECU but can't see the ethanol percentage on the ECU, just zero. What have I missed? GND and 12V come from battery to ethanol sensor.

-Does anyone know the knock frequency for 1.8T engine? It was not listed in help file

-Is it possible to get grams/second reading from Bosch MAF sensor. I have it on bigger Audi RS4 housing. I know it's not needed the engine to run, would be nice to know roughly. I can set voltage vs g/s values to table but how to add more columns to that table?

-Please explain me torque management. ESP needs this to work? At the moment I have ESP light on. At first I think the ESP was happy, what have I done :oops:

Any help and comments are much appreciated!

Aux 9/10 supply voltage tapers out -> Fault 73 / 77

in G4+

Posted

Some progress on this one. Took the cover that has the position sensors off from the TB. Noticed that is the same as mk2 Ford Focus 1.6 Ti-VCT TB cover. Switched them over and got right away limp mode and errors on Focus and Caterham trottle worked fine. I wash in a rush so short tests. Focus errors might be due to that I just threw the new cover in there, no calibration. On the Caterham I did calibrations before startup. Ordered a new TB, will report once I got it installed if it cured the problem.