-

Posts

16 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by Sir Alfred of Hors III

-

-

On 4/3/2021 at 5:05 AM, Adamw said:

If your car has a high level tacho that was originally connected to the ignition coil primary then it likely won’t work connected directly to the ecu. A tacho booster is generally the easiest fix if your tacho is a high level type.

Sorry to bump so late, just wanting to check my wiring with the new setup.

So, I've opted for a boost controller, an ethanol content sensor and cop. And a wideband obviously.

So, to make sure I have it right there.

I can use ign 5-8 for the signal of the CoP, save cutting original harness.

I can then use a relay from the battery (or otherwise just ignition switched power from somewhere) for the power. Then just ground.

Then for boost solenoid and ethanol content, I would use analogue volt wires for inputs? and same deal for power and ground

Then for wideband, use can2, and the white connector to dtm adaptor, then power and ground as per the others.

Nothing special I'm missing there I assume? Don't need to run specifically off ign1-4 for cop?

If that's all gucci, I'll get the wiring going asap. Bought a whole bunch of dtm plugs and tools finally, so should be able to get some neat dtm connections happening. Hopefully make it all quick connect, and not messy af -

On 6/22/2022 at 5:54 PM, Adamw said:

That cam position sensor looks to be in about the right place so I think your offset should be close enough for a spark to be able to make it out of the distributor.

And it should spark in test mode so that also suggests your no spark issue is no related to incorrect offset.

If it is not the coil then the most likely culprit is the ignitor, this is the this electronic module inside that the coil -ve wire goes to. So swap that if you have a spare.

For anyone who finds this in google, the distributor was the issue. Got a brand new one off a friend, and it ran on the stock ecu. Rich as all hell, but it ran (1000cc life).

So, got it timed now, Still isn't running, but is close.

Does try to fire as soon as you turn the key, then nothing.

So, at least I know distributor is good, and it can run. think it's about time for the tuner to do the rest haha

Edit: got it running. It wasn't just the distributor. The intake manifold had a hole in it, and was sucking air through there, causing it to rev to the moon. Haven't put the link back in just yet, but I have a sneaking suspicion that was the issue. Will update if it works now -

1 hour ago, Adamw said:

That cam position sensor looks to be in about the right place so I think your offset should be close enough for a spark to be able to make it out of the distributor.

And it should spark in test mode so that also suggests your no spark issue is no related to incorrect offset.

If it is not the coil then the most likely culprit is the ignitor, this is the this electronic module inside that the coil -ve wire goes to. So swap that if you have a spare.

no bingo there either.

Still getting trigger errors and no spark.Doesn't spark with stock ecu seemingly. Something is up.

Might have to sit on it and give it to the tuner to deal with at this point haha. Dude knows hondas inside and out seemingly, so should be able to find the issue. I'll inb4 I've forgotten something, or missed something and not realised.

Thanks for your help man -

Don't know why I missed it before, but solo white mark is tdc, triples are various points btdc.

Some of the diagrams also show another point to measure from.

Will test for spark tonight anyway, see if the coil was the answer. And if not, go scouring.

Either way, ty for your help, seems it's not ecu related, which narrows it down a lot hahaEdit; Nevermind, that's cam position sensor apparently. Tdc is deeper inside. Right behind the coil thst is easily removable

It's a learning experience. Always something new to learn on this, which is nice

-

22 minutes ago, Adamw said:

Alright, so, replaced the coil while I was in there. But yeap, definitely off.

Also wasn't sparking from coil spring to ground on test, thus replacing coil.

Still nothing with proper coil.

Pics; first one with the sensor thing lined up to the middle of the hole is middle of the three lines on crank pulley.

Other one is lined up with the single line further off, which might be btdc?

Don't worry about the belts, they have managed somehow lmao.

But yeah, it's odd that it was all set up before, and this is all mechanical, isn't it? Unless one of those dizzy bits can be adjusted by the ecu?

-

11 hours ago, Adamw said:

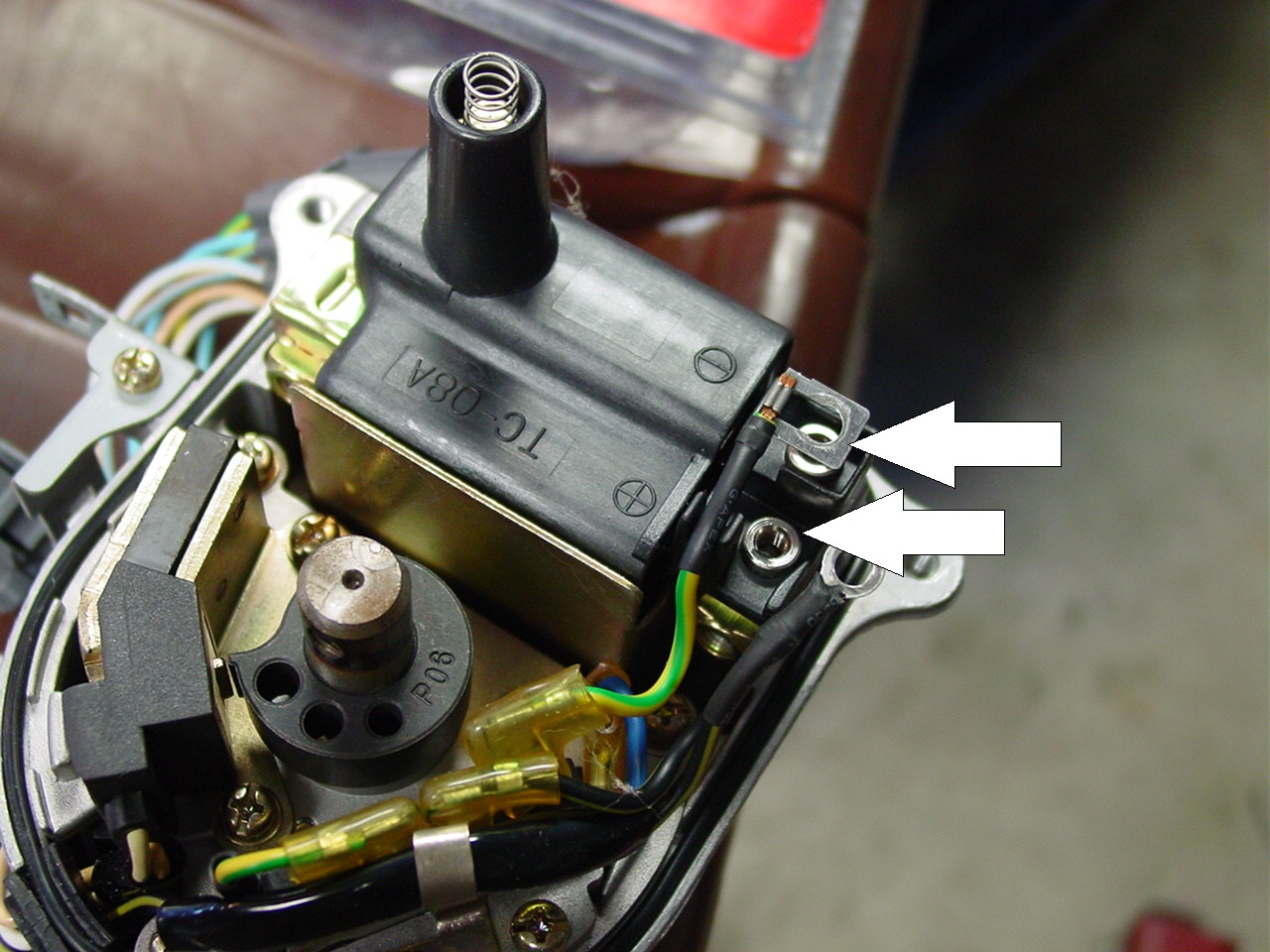

I actually wanted to see the sensor and tooth location in the distributor which is under the black cover. Not sure how easy that is to get too.

While you have the cap off, you could run a small piece of wire from that coil spring to somewhere close to ground, then turn on Ign test #1 to see if you get a spark there.

I'm fairly sure the toothed thing is buried deep under all the components. Unless it's this one, which is just under the black cover (stock picture for effect)

In the meantime, I will test the spring and ign 1 test, see if anything happens.

At the very least, that might tell me whether the distributor finally shat the bed.

It is an ebay one, so was kinda destined to die, apparently.

Only thing I can think of that might have caused any issues, is potentially the cap being left off for a few weeks, but it was in the garage with no water access.

I do have a spare coil from my other distributor (oem one), which I think I said above, but was worried if it's settings related, it might blow that too. But, you said settings seem fine, so might try that worst case.

But, if the distributor itself is the issue, time to wire in the CoP conversion, hah.

Anyway, will be back soon with an update -

14 hours ago, Adamw said:

Nothing much looks out of place in any of your data. In the log it appears everything is there that is needed for a spark. I wonder if it is just the offset is off by quite a bit and causing the spark to occur when the distributor rotor is not pointing at a post in the cap.

If you turn the engine to TDC1 by hand and pull the distributor cap off then give us a photo of where the "sync tooth" is in relation to its sensor I should be able to estimate whether the offset is in the ballpark or not.

So, the weird thing is this hasn't been touched since it was running. But it looks fine. Albiet abit of a dark mark on it. Did give it a buff to see if that was it.

Bottom left is 1, top left is 3, top right is 4, bottom right is 2.

The points on the cap look fine -

helps if I post the right log

-

Hopefully that's what you're after haha

-

Yoo,

So, just in the process of getting the car ignition and base stuff all sorted so I can make sure everything works before giving it to a tuner.

So, we went to set up the trigger btdc stuff, and discovered there is 0 spark. Triggers are set as the manual specs. everything is set up how it is specified to be in the manual. rising rate distributor, 1342 firing rate, etc etc. Fuel is currently off.

Trigger 1 and 2 status are on. rpm is 200~, there is trigger errors though. Unsure on what is causing them yet. did think it was from trigger setup not properly timed yet.

But nop, no spark.

ignition cut isn't on, rpm limit isn't on.

attached trigger scope. Unsure if it's reading too many triggers, or I'm not reading it right

Distributor is also getting very warm while ignition is on. hasn't been a time where it was connected whilst the distributor was in opposite polarity.

At some point I will give it to a tuner to sort, but just making sure I haven't got any bad parts first

-

17 hours ago, Adamw said:

If your car has a high level tacho that was originally connected to the ignition coil primary then it likely won’t work connected directly to the ecu. A tacho booster is generally the easiest fix if your tacho is a high level type.

Having a look around, found another one with an ek and similar looking scenario. Looks like it is high level, so booster it is.

Cheers for your help as per usual, always got the goods. Both now and in the past haha -

On 10/18/2020 at 4:36 PM, Adamw said:

Yeah the T1 Cam trigger is definitely a better option than the AEM EPM, although I think I remember there was a user on here a little while ago that received one DOA. Again I think probably no better than a stock distributor though. Both of these items were considered upgrades only because the old AEM honda plug-in ECUs that were common in the USA in the '90s & 2000's had crap VR conditioners that would rarely work with the factory distributor.

Sorry to bump so late. Been in talks with a friend, and he's said oem dizzy would be best, and agrees with you. He's supplying me with a bunch of parts to get the turbo swap all ready, but he wants to check what the best method is for CoP conversion.

I've been scouring the forums a little bit for info regarding it with oem dizzy. Seems it should be fairly easy to wire in. Just wire up the coils, set the ecu, pull the unneeded bits from the dizzy and off we go.

But, I've seen pretty much only one person say rpm gauge doesn't work. Was ages ago, and that it needed a tach booster. Is that still a thing? Or rather, is that a thing for obd2a?

Just trying to suss out all the options and things I need, and what wiring needs to be done, so I'm ready to go as soon as I get the parts and time.

Friend can get me some or most of the parts I need to rebuild my oem dizzy. Current ebay one probably won't be as good for signal no doubt lmao. -

17 minutes ago, Adamw said:

Yeah the T1 Cam trigger is definitely a better option than the AEM EPM, although I think I remember there was a user on here a little while ago that received one DOA. Again I think probably no better than a stock distributor though. Both of these items were considered upgrades only because the old AEM honda plug-in ECUs that were common in the USA in the '90s & 2000's had crap VR conditioners that would rarely work with the factory distributor.

From my understanding, it's mainly because the only real way to go with the hondas is the oem distributor, cause it seems the aftermarket scene is full of duds. No idea why, but apparently they either leak straight away or shortly into life, or just fail. And because oem is the only way to go, and rebuilding is getting harder and harder, doing this is a good way to avoid bad seals and bearings and what not.

That and the internal parts not being the most accurate, so this is about the same, but at least puts the ignitor/ coil on top, making it better and what not. Plus also gets you with the whole not dealing with aftermarket distributor seals and stuff.

I've been looking around for options, but it seems either rebuilding and running a cover (though I'm struggling to find the parts needed to rebuild, and local honda can't get anything bar the rotor, cap, coil and inducer. No bearing, seals etc. Could potentially get the bearing from a local bearing shop), or running the epm.

It does seem like a good option at the least if it does work, cause that way you don't need to worry about distributor bearings and seals shitting the bed hardcore, and messing up timing and stuff. But, I suppose that's also a potential for the epm maybe?

I dunno. Just seemed like the best way to go from what I could find, aside from the t1 cam trigger. But the cam trigger thing made me wonder how it'd do crank timing, whether you'd need a crank timer as well or something, or if it does that as well on the cam gear. And then what you'd use to cover the hole from the dizzy.

But, ideally leaving the oem dizzy would be my aim. Just cause of how hard it's getting to source them, and get good replacements and/or parts to fix it (at least from my poor search skills) -

8 hours ago, Adamw said:

Avoid the AEM EPM, I have seen many users with different ecu's have many problems with them. The stock reluctor in the distributor is a more accurate and reliable trigger.

Your proposed ignition pins are correct.

Only issue with that is the stock distributor is basically about to explode/ seize.

I can rebuild it, but figured the epm would be a much easier option.

I suppose there is otherwise using a cam gear trigger point. That's another thing that's sold and is apparently more reliable/ accurate -

Hey,

So, my distributor is on the way out, and I'm in the process of looking at replacement options.

I've been planning on turboing my b16a2 for a while now (have half the goodies. Just need manifold and exhaust stuff), but figured it might be worth going coil on plug for ease of use, since the dizzy's tend to be a pain to source (well, lasting ones anyway).

So, I looked around, and found a few guides for it for obd1 engines, and/or the aem cop kit itself.

But, k20 coils and the aem epm seems to be the better way to go, since it can handle more boost and power (vs the aem pencil coils and ignitor being limited to 15psi).

I have yet to install the link, so doing this I'd probably get it all installed. Engine is still stock, but it'd save me a bit of drama down the track more than likely. Can at least get the base stuff dialled in before turboing I guess, if that helps?

So, looking all around for diagrams and write ups, I've found basically nothing for obd2 setups. Only obd1, or aem cop kits.

About 3 hours of scouring, and finally looked in the manual, and found there's 4 ignitition signal ports.

So, if I'm understanding this correctly, using the hussain-vtec diagram; of the epm,

pin 1: crank signal/ trigger to c-12

pin 2: ground to head, along with the coils grounds to head.

pin 3: cam signal/ trigger to c-4

pin 4: ignition pos to a-24 plus coils pos

Then coils signals themselves;

Cyl1: a20

cyl2: a21

cyl3: a31

cyl4: a32

Does that seem right?

Am I missing anything from the equation here? I feel like I am.

Might've mixed up pins here or there. Using the above mentioned hussain-vtec diagram (link) that was corrected by another user, which got him going. Then finding the obd1 ecu pinouts, and the obd2a pinouts, and finding the matching thing. Then also double checking on the manual for the hc96x.

Is that pretty much it?

Cause if so, I'm down to boogy and get this car not running like poo, and on the road to a stronger/ more reliable boost setup down the track (if it all goes ahead, otherwise just a fun daily na setup).

Cheers

hc96x COP wiring help (k20 coils, aem epm)

in G4x

Posted

Alright, need a few more bits then for cop haha.

Thanks for that. Will get the other bits started and the cop once the pins arrive.

Think that should cover all my bases now haha.

Thanks heaps for all your help