lekonna

-

Posts

134 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by lekonna

-

-

what happens when you re-calibrate the TPS when it's in the new adjusted position?

well, in theory you would loose some resolution from the sensor since you are not exercising its full range

of movement. in practice, i don't know if it matters or not. The question is, are you now hitting 100% from the

sensor earlier than your throttle is really fully open ?

-

Hi, this is about something that's been going on from day 1 of getting my motor running but I'm finally getting around to asking.

I'm running a V44 and when at part throttle (loaded OR unloaded) right at 2k rpms my motor stutters/stumbles/hesitates. I spoke with the shop I purchased through and they had me clock the TPS so it read the maximum voltage/percentage at idle it could, after doing the tps setup with it reading the minimum voltage/percentage. Meaning at closed throttle it reads about 16% throttle.

This made it WAY better, and almost completely livable. But cruising/part throttle I still get a stumble/hesitation when driving around. That and I can't use DFCO.

My engine is a 2.0l Toyota 3S w/variable cam timing. It is running ITB's and the throttle sensor was purchased brand new.

Andrew

Well, i had the similar problem with my 2jz. the root cause was that you need to calibrate the tps with the car powered, other ways it shows different numbers than when the car is turned on. This results to the situation when you are running with low load on the street, the TPS reads too low and the overrun fuel cut cuts the fuel. (you can also disable this feature to check if it is the cause, under fuel tab -> overrun fuel cut).

Messing with the throttle calibration so that tps shows 16% when closed just seems bit silly to me. what an strange advice from a shop.

-

Hi all,

i've read some old topic about il pressure sender at viewtopic.php?f=3&t=490&p=3469&hilit=oil+pressure#p3469

I've got the same sensor, i was just wondering the table since RayHall seems to setup the resistance values in the table so that

1000Kpa hits the 130Ohm column in the table. Should i just follow what the man said or interpolate so that the 160ohm is at 1000 Kpa place?

It propably has to do with the internal pull-up inside vipec, so it is pretty hard to go and guess what the correct values are without knowing what

the pull-up resitor value is.

br, Janne

-

Okay, thanks!

Just got an impression from Ray's explanation that while using open loop -method, just tune the engine to 14.7 AFR at 100 kpa load, the math would do the rest and the ECU would then use the AFR table to calculate the sufficient opening for the injector. The reason I put up this thread, was that different size of turbos pumps air into the engine with various amounts, meaning that one would pump 60 lbs / min and other 80 lbs / min at 300 kpa level, how would the ECU determine the required fuel just out of the MAP which could be the same using different turbos but the amount of air entering into the engine would differ greatly between different turbos used in the same engine, but giving equal load and airflow at 100 kpa where the 14.7 AFR was tuned as starting point for the calculation.

OT: question, are you by any change from finland? i would have send PM but its not enabled in the forums.

-

any chance you guys would enable PMs on the board again?

-

stripped the car down

cage installed

and a new coat of paint

back from the paint and started installing skirts, spoiler, doors, interior ..

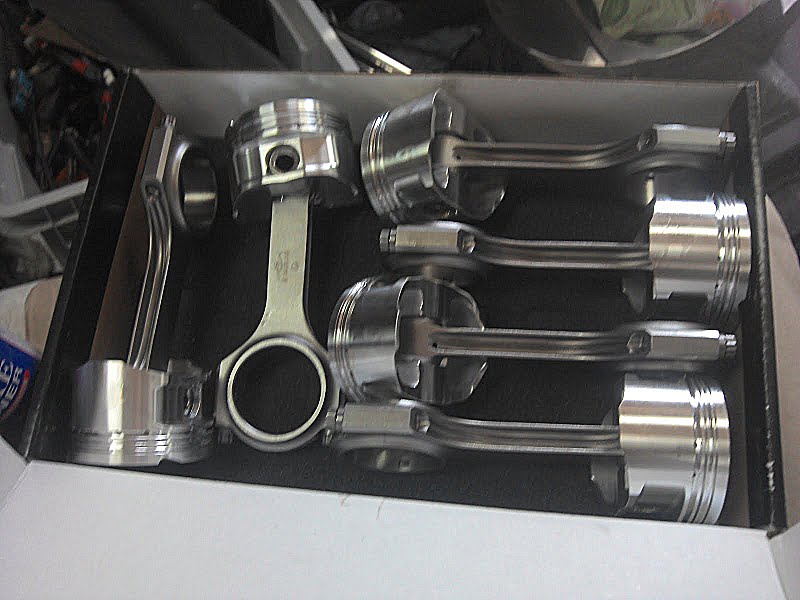

high cr engine, around 10.4:1 coming together

the block is pretty rusty from the inside on the water passages, ah well ..

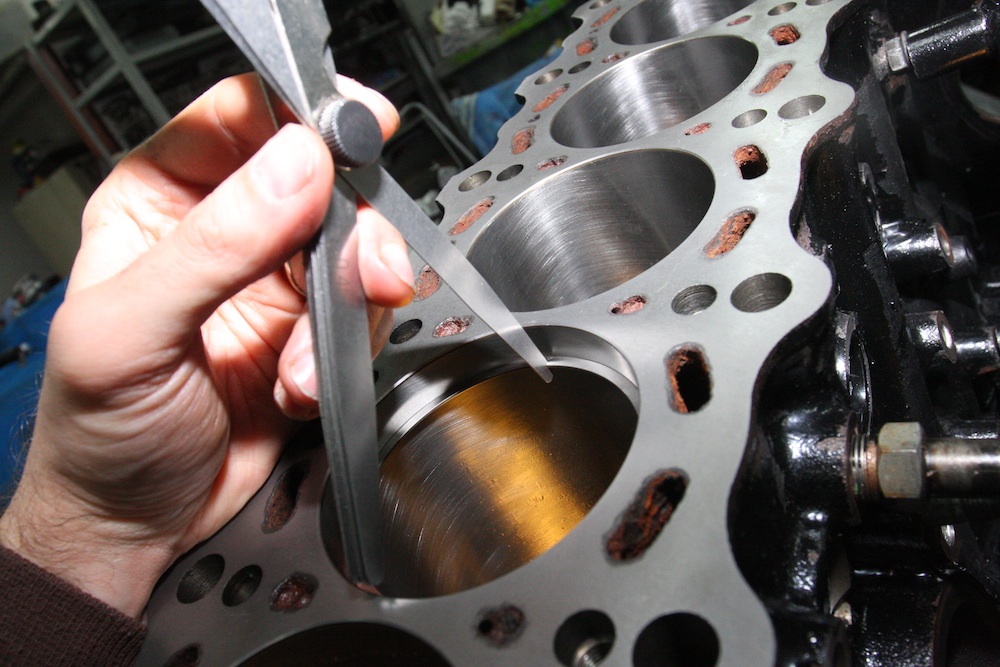

atleast the stuff that could be is now machined to spec.

made a housing for electric fans

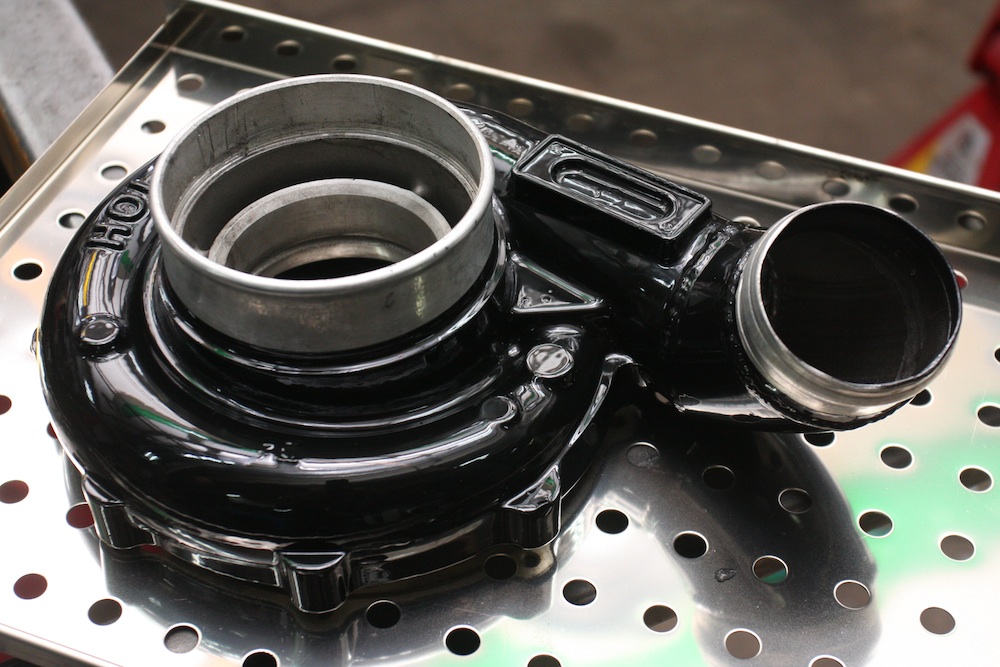

powder coated stuff

things to be done:

- finnish the engine, waiting for the head and few o-rings for the oil-pump.

- install bucket seats and racing harness

- new engine wiring from tt-speed.

- make a bracket for the 034 coils

- powder coat the fan housing, intake manifold, valve covers ..

actually, there is such a shitload of things to be done that it is better to not think about it

think i'll head back to the garrage now ..

think i'll head back to the garrage now .. -

thanks a bunch. since it seems to be impossible to edit the axis on the injector dead time chart i had to interpolate by hand,

the table on the site doesn't have the same granuality as vipect expects.

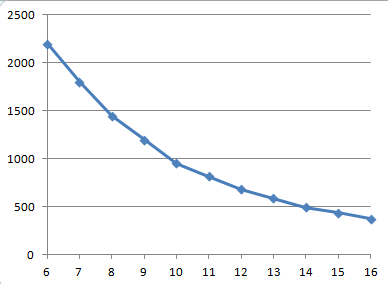

this is the curve i guessed based on those values

which resulted in following table:

-

as per topic,

does anyone have a dead time table handy for these bosch injectors?

i believe they are the same than ID2000

2JZ GTE VVTiBase Map

in Guest

Posted

i could use one as well, just for study.

[email protected]