lysaer

-

Posts

43 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by lysaer

-

-

On 11/26/2018 at 4:24 AM, krohelm said:

I use DTM all over the place. It's worth the scratch to get a crimp tool in my opinion! This is the one I use for DTM's: https://prowireusa.com/p-1813-deutsch-dtm-mil-size-20-crimp-tool.aspx

@Adamw: Totally, that's where I'm at but in my case 2 had the same problem despite providing clean separate power. I'm in love with the cap fix :-). If y'all want to try the dance again I've got my CAN-Lambda mounted in a convenient location & could return you this one for analysis. Not sure if we'd root cause it, but anyways feel free to reach out.

I hope the cap fix works for you too @lysaer. Your thread sounds familiar

Re-did all my wiring etc and added the cap but had no luck, today I swapped out the sensor and now it is all working, it needed all the power wiring sorted anyways and I have left the cap in so hopefully now it all stays working

-

On 11/24/2018 at 4:30 AM, Adamw said:

Yes, assuming that jumper pack can be forced to stay on that will be a good test.

Switched out actual sensor today and is now working , will post a log up for you in a bit

Thanks for all the help, at least I got all decent wiring etc running there now as wellUploaded log to my Google Drive here as I don't have any space left on the thread for uploads

https://drive.google.com/open?id=10vuPvfWhPcwv-wVLWtquA_ZmPBnqB6QV

I have an issue with my A/C where it stalls the engine, it would be near the start of the log, not sure if that is related or how I could remedy that as well

Thanks again Adam -

On 11/24/2018 at 4:30 AM, Adamw said:

Yes, assuming that jumper pack can be forced to stay on that will be a good test.

I know you mentioned in the other thread about it being a faulty unit, but remember I fitted the new unit so right now there is a brand new one in there

I have got the capacitor so will connect that to test, if it ever stops raining in the UK.... -

On 11/24/2018 at 11:15 PM, krohelm said:

Holy smokes, why am I only hearing of this now? I added a 22uf Nichicon (switching the power wires to nicer crimped Deutsch pins too) and just started the car, 0 waiting with key on. Within a few seconds, while it was running, the LSU 4.9 was operating normally. This has never happened before.

These CAN-Lambda devices should come with the capacitor already on the plug, or better yet... in the potted enclosure. The stark difference in operation is nothing short of miraculous.

What size deutsch pins are they please, going to redo mine as well

-

On 11/24/2018 at 4:30 AM, Adamw said:

Yes, assuming that jumper pack can be forced to stay on that will be a good test.

Tested with the jumper pack today, still same error 16 and 33

I've ordered a 22uf capacitor to give that a try as well

-

On 11/24/2018 at 2:39 AM, Adamw said:

I have just replied to your other thread, I think it will be easier to keep troubleshooting all in the one post.

Yeah I just was having a search and it seemed like the exact same error so was going to see how he resolved it

23 hours ago, Richard Hill said:I have found that the CAN Lambda is very susceptible to transient supply dropouts. The alternative wiring below is in the new CAN Lambda instructions and includes a 22µF capacitor in the supply to the unit. I have had several CAN lambda units that report faults and the addition of this capacitor has solved the problem every time.

I think Link should update the online PDF file to make this the recommended setup, as the diagram below seem to only be included with the new CAN Lambda modules. (IMHO, the addition of the 22µF capacitor inside the CAN Lambda module would solve the problem long term).

Regards,

Richard.

Interesting, I will look into this, going to connect direct to a battery jump pack for now

23 hours ago, AbbeyMS said:So the capacitor "quietens" the 12V signal down @Richard Hill W ehave seen CanLambda stop working when more electrical items are turned on , pulling the 12volt supply from the battery sorts these issue normally but cant be a long term fix

14 hours ago, krohelm said:Holy smokes, why am I only hearing of this now? I added a 22uf Nichicon (switching the power wires to nicer crimped Deutsch pins too) and just started the car, 0 waiting with key on. Within a few seconds, while it was running, the LSU 4.9 was operating normally. This has never happened before.

These CAN-Lambda devices should come with the capacitor already on the plug, or better yet... in the potted enclosure. The stark difference in operation is nothing short of miraculous.

Hmm I might give this a try as well since it seems to have worked for you

-

16 minutes ago, Adamw said:

Ok, so you still have error 16 present. So I understand you now have power via a relay direct from the battery? Have you removed the original wires? Is there anything odd in this car like the battery moved to the boot or anything?

Do you have another separate battery or a jumper pack or something that you could try powering the CAN lambda from as a test?

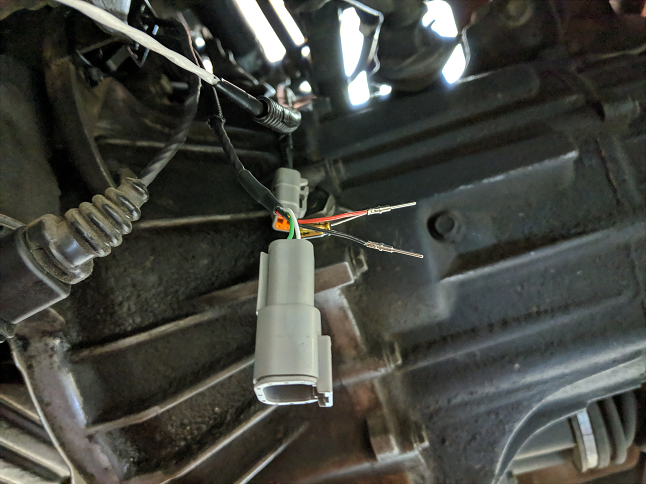

Yeah power is now direct from battery via relay and I replaced the wires going to the CAN Lambda with 14awg

Nothing unusual, battery is in original location

I have one of these jump starters which I could connect the wires to and run it in the car to test

NOCO Genius Boost Plus GB40 1000 Amp 12V UltraSafe Lithium Jump Starter https://www.amazon.co.uk/dp/B015TKUPIC/ref=cm_sw_r_cp_apa_w2l-BbPEYM8GH

-

On 3/15/2017 at 5:32 AM, krohelm said:

Iterated with Simon, and regardless of the log files and voltmeter measurements - I ran a new power supply pair and it works (I tried this parallel twice before). While I'm curious what was wrong with the +/- I had, I just do not care enough to root cause it; my car works and Link tech support is amazing. On to tuning!

Sorry to resurrect an old thread, I think I am in a similar scenario to yourself as am getting the same errors.

How did you end up wiring it in the end to resolve it and what kind if lengths were your +/- cables ?Thanks in advance

-

On 11/19/2018 at 10:01 PM, Adamw said:

What are the lambda runtimes showing here:

Was unable to check yesterday as was raining all day so couldn't pull apart

All blocks are now green in the CAN tab and in the ECU status tab it shows CALIBRATION but showing error 16 and 33 under "lambda 1 error", have a log but I don't have enough space to upload it so have linked to my Google drivehttps://drive.google.com/open?id=1N-qAqRcEqtmGs05HKuQLXJz276YgCEHa

-

58 minutes ago, Adamw said:

What are the lambda runtimes showing here:

I'll check tomorrow when I pull it all back out

-

36 minutes ago, Adamw said:

Your CAN is working fine so dont bother messing around with that. You need to look at the ECU Status tab of the run times. You still have error 16 showing in your log, so it is most likely still a power supply problem.

Did you go directly to the battery like I suggested? Did you disconnect the existing power wires?

Did you do this? This would be the ideal set up.

It is not EMI, the CAN is talking fine in your log. It is the power circuit that is not happy.

Yup went direct to battery and fitted the relay, before putting it all back tested it and all blocks were green on CAN 1, started engine still all green, switched off engine, exited software, reloaded software, switched it all back on and still all green

Put it all back together and now same red errors

Really appreciate how helpful you guys are

-

So I boxed it all up and put it back together and now the error is back :/

I wonder if there is some EMI, I have ordered some copper sleeving and will pull it apart again tomorrow and see if the error goes away -

I want to make sure that I keep the good current coming directly from the battery, if I wire in a relay to work with ignition on the 14 gauge wire I have used directly from the battery will that be ok, or will it cause interference again or power up issues ?

-

4 hours ago, Adamw said:

Its possible but error 16 is usually power supply related.

So connected directly to power and this is what the runtime values shows for CAN

The lambda is still not showing a value

restarted ecu and now

Ok, fitted a brand new CAN Lambda, kept the old sensor and connected it up, disabled the gaugeart dash on CAN 2 and now am Green, but still not showing an AFR reading in the software in the lambda box, added log as well

-

3 hours ago, Adamw said:

The “find devices” tab is only used for Link CAN Lambda’s, it will no show other devices.

Great, noted

Could a fouled lambda sensor give the same error I am receiving or is it specifically related to CAN lambda power?

-

On 11/16/2018 at 7:16 AM, Adamw said:

I would go direct to battery as a test, if that works try the isolator.

There is no EGT set up in your map.

I ran through the CAN setup and when I do find devices the only one showing up is the CAN lambda, would that be correct or should there be other sensors, I'm guessing EGT?

-

On 10/30/2018 at 8:09 AM, Adamw said:

Yes download the latest PC Link from our website, that contains the latest firmware, then do this: https://www.youtube.com/watch?v=u54915wuLYc

Yes, Lambda/AFR will show 0 if the sensor is in error condition.

I have updated the firmware and I checked the voltage on the CAN Lambda it is showing 14v when engine is on

Going to check wiring properly tomorrow to make sure cables are large enough and see what they are connected to in case of interference as I did not install itI have a direct to battery ignition relay for running equipment in the front of the vehicle, like LCD dash, cameras, telemetrics etc etc

https://www.amazon.co.uk/Stinger-SGP38-80-AMP-Battery-Isolator/dp/B001HC6UJ0

If I connect it directly to that for testing purposes would that suffice, or should I just connect directly to battery live and bypass ignition then run a LOG and test ?

Also as a side note, is there EGT data being displayed in the log as I am unsure if the EGT sensor is connected

Thanks for all the help so far

-

On 10/29/2018 at 2:00 AM, Adamw said:

Sorry, I should have looked closer, I missed the CAN Lambda. It is showing error code 16, which is usually caused by poor power supply. You will need to get that looked at, make sure it gets its power from a source that is capable of at least 8A (and wires are big enough), and sometimes they can be upset if connected to the same source as something that generates a lot of inductive noise such as a idle valve or VVT solenoid.

You should update firmware to 5.6.5, in that we added an improvement so that the CLL is disabled anytime the CAN Lambda is in error so that will prevent this issue from happening in the future.

I will check the ignition power it is connected to to make sure there are no issues and also update the firmware on the device, is the firmware just downloaded from the site ?

I did notice the Lambda gauge on the software was not displaying anything, is that because of the error or do I need to enable to something else so it shows AFR ?On 10/28/2018 at 7:42 PM, cj said:Did you run through the can lambda setup here

https://linkecu.com/documentation/canlambda.pdf

I can see the channel set up, but cant see the bit about assigning it to lambda1 because the ECU is not connected. your lambda1 values in the log are all 0 so it looks like something is missing. On second look at it, I can see the lambda1 error state bouncing around a bit. Have you double checked the wiring to the lambda sensor? If it is talking to the ECU, its not sending anything useful. While this is clearly a bit of a problem, its not likely to affect 1 cylinder more than the others.

That injDC value turning red is normal. It just shows that its a changed value vs what it was. remember to save the changed value to your pc by pressing f2 (or file>save / save as) AND saving it to the ECU by pressing f4 (aka store)

I did not fit the ECU or sensor but I would assume the mapper did when the car was originally setup

I pulled the plug again today and there are small signs of oil on it, since the compression seems fine I am guessing it might be a valve seal that has gone, I think next step will be a leakdown test to see if I can hear any air coming out the head

-

2 hours ago, Adamw said:

One problem I see is closed loop lambda is enabled but there is no Lambda sensor assigned so the CLL is adding 10% fuel all the time. 10% may not sound like a lot but you if it was originally tuned to say .9Lambda at idle then with +10% you are at 0.8Lambda which would be in the territory where plugs could foul. I suggest tuning the CLL off for now.

HKS made an aftermarket VVT kit for the RB26 "HKS Vcam", from the setup it looks like it is running one of these.

There is a lambda on the CAN connection ECU CONTROLS --> CAN SETUP it is on CAN 1, I did not do the map on the car originally so where would I disable the CLL ?

4 hours ago, cj said:I cant see anything specific to cylinder 1 in that log. Is it only this 1 cylinder that is causing dirty spark plugs? Are you sure your injectors are all delivering the same quantity of fuel? 1 could be partially blocked or leaking and if the other cylinder are all a bit rich/lean the opposite way, the total engine lambda will look correct.

As far as general things you might want to look at from that log:

you dont have any lambda readings, that makes it really hard to guess where you are rich/lean.

You have a speed input on DI3 of Left Front wheel, but in speed sources you have selected Left Rear wheel, so as far as the ECU is concerned you are at 0kph all the time which means anything speed dependent isnt going to work correctly - idle speed lockouts, traction control, gear detection, probably a few others.

You have your second fuel pump set up to only turn on at 70+% inj DC, and it looks like you only hit 70% at about 7500rpm under full throttle - basically that second pump almost never gets used. Not sure if this is on purpose or not. - see at 51:22 for the only time this seems to happen. Looking at your fuel pressure logs, its starting to drop off by 5-6 kpa above 50% inj DC so maybe drop the cutover to 50%

your VVT target tracking is pretty slow, and seems happy to stop moving when you are within 5-6% of target. This is going to make it tricky to get consistent AFR between runs as your VE will be slightly different. What sort of engine are you actually running? I'm not really a nissan guy but I thought variable VVT was only on the R34 RB25's but your title says its an R33 GTR.

It is only cylinder 1, I had the injectors taken out and flow tested and they are all running perfectly, so am sure it isn't a sticky injector

there is a lambda sensor installed on the CAN, if I go to ECU CONTROLS --> CAN SETUP it is on CAN 1

I dropped the IN DC% on fuel pump 2 to 50% and it shows the 50% figure in red, is that an issue ? Fairly new to settingsAs @Adamw stated I have the HKS V-Cam in the vehicle, mainly it is a HKS 2.8, V-Cam Step 2 head, twin 2530-kai turbos and a lot of other supporting mods

I guess it could be a valve seal has gone and some oil is getting through, the build is fairly new with all new components and only covered about 8000 miles though, so wouldn't think it was that

-

here is a copy of my map as well

-

Hi all

Recently my cylinder 1 spark plug has been fouling badly and becoming carbonised

I have done a compression test and compression is perfect and equal across all cylinders

I took a driving log and was wondering if there was anything in the log that might indicated why it is fouling up, the log is pretty big so zipped it with 7zip

Thanks in advance all

-

6 hours ago, Adamw said:

Something doesnt sound right there, I would have expected RPM to increase with that much, maybe your idle control isnt even working. Can you do a short PC log of a few minutes of running/idling, switching AC on/off etc.

https://www.youtube.com/watch?v=_P1LRANeO4A

Will do that today for you

-

On 5/29/2018 at 3:27 AM, Adamw said:

You have zeros in your AC Step table, this table determines how much extra the idle valve opens when AC is on.

Try putting about 5% in all of these cells.

So I have been testing with different variables the last few days started at 5% then 6% up to 10% but still getting stalling when coming to a stop

I stuck in 25% just to test it at standing idle and as soon as I turn on the AC it just dies.

Wasn't sure how much over 10% I should go for driving or if there is somewhere else I should be looking at resolving this

Thanks again in advance

-

r33 gtr check 2nd fuel pump cut in duty and coolant warning temperature

in G4+

Posted

Hi all

on my r33 gtr rb26dett

How can I double check my 2nd fuel pumps cut in injector duty please

Also how can i increase the coolant warning, I think currently it warns me with the check engine light at 100c which is to low for the hot weather

Thanks in advance all

atest-gtr.pclr