434josh

-

Posts

94 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by 434josh

-

-

Thanks Simon. What makes the signal so weak? The post is similar in size the the cam sync I have been using for 3 years. Just curious.

The OEM sensor is VR, I can do a Hall effect if needed.

-

Hey guys,

My time with the 6 liter Ford V8 has come to an end and now a 1400+ HP Barra is in the works. I'm in the US so the Barra knowledge base is limited and the Link users even more so.

I have basically everything lined out except cam timing. The vct's are deleted since I have larger cams and stiff springs. The cams has multiple sensor teeth on each but I feel I only need one tooth total. Which should I keep and which can be cut off? I only need one cam for signal and I have had great luck with approx 40* before the missing tooth on the crank. Should I stay the same with the higher revving Barra?(crank has always been 70* before with cam at 40* before missing tooth on a 36-1 setup)

The bara is 24-1 tooth I believe.

Any advice? Read from intake or exhaust cam? Which tooth to keep?

-

I am using an AEM brass body pressure sensor. It is the STD Bosch calibration. I have one on my regulator and one in the injector rail.

-

2 hours ago, Simon said:

Yep that would be the set up to go with. The second wire connects to sensor ground.

Thanks Simon,

Now the second part of the question. I am setting up for a roll race this weekend. I want to setup a pushbutton speed limiter of 60mph and at the same time create an anti-lag.

Transmission is an auto and I am turbo charged and using dbw. What is the best way to accomplish this? Huge timing retard with the speed limiter?

-

My transmission has an output shaft speed sensor built into the case that I want to utilize. Not specifically to indicate speed for driving but to activate an output at a consistent time based on speed. The sensor is a 2 wire VR.

I am using DI2, RR Speed, no pullup and falling to start unless suggested otherwise. Correct?

The other question is, what does the second sensor wire hook to? Sensor ground or a 5v ref? I have only used VR sensors for ignition that specifically have pins for both wires so I want to make sure I don't cause any ecu issues by hooking it up incorrectly.

Thanks for the help.

-

I had a similar issue. The ground triggers from the ecu switch to ground when you key off so all items that are hot key off will see a ground signal. I fixed by adding a 125amp ignition switch triggered relay that powers my guess box. That kills the 12v to every solenoid when I key off.

-

-

Thanks Adam, I will certainly install the update.

You mentioned using a 4d ignition table for variable torque reduction, would that be in conjunction with the gear shift control or something by itself? How would it be tied to the od shift output?

As far as the between 40% tp and 85%, no reduction is required and I would just want it to not shift at all. The logic behind this is if I am cruising on the hwy, the tps will be low, definitely below 40%. If I am racing, TPS will be high, above 85%. If I am simply playing around on the highway and doing a fast accel, likely I am not wanting to push past 120 mph anyway so I would want to stay out of overdrive. 3rd gear will do 150 mph and od is capable of over 200.

Downshifting from od is also where that window comes into play. If I wish to accellerate past slower traffic and push the tps past 40% I want it to kick out of od and once throttle is pulled back, shift into OD again.

-

I know the ecu wasn't intended to do this but I am trying to make my Link Extreme control my Overdrive and TCC lockup.

I think I have found a way but I am not 100% sure if I am understanding it correctly. My auto trans has a full manual valve body and a ground triggered overdrive and lockup. OD is only possible when the trans is in 3rd gear (od is 4th) and the torque converter can be locked at any time but i only wish to lock it in 3rd and 4th. This question is really just about activating overdrive based on a few conditions AND most importantly pulling power upon the shift. The overdrive band and solenoid can only handle about a 500hp shift and my setup makes closer to 1100 at full power. I need to reduce the hp/tq by about 60% for 300-500ms and them ramp it back in smoothly. Can I do this using the gearshift control feature? I have no way of inputting what gear I am in however I can set some conditions based on speed and tps that will only be possible when I am in 3rd gear anyway. I have attached a tune and if you open gear shift control, Aux 1, virtual Aux 1, and DI1 I think you will see what I am trying to accomplish.

I want the ecu to OD shift the trans as I pass 55 mph with a tps of less than 39%. This shift does not need torque management so I locked out gear shift control below 40%.

AT over 85%tps - full power- I do need torque management so I will tie the shift signal from Aux 1 into DI1 and the transmission to signal gear shift control to cut power for the 85% - WOT shift at 140 mph.

Does this tune care for what I am trying to do? Am I understanding the gear shift control correctly?

Is there a better way to accomplish this?

Thanks.

https://www.dropbox.com/s/t4na4crzf0amq76/Ford 363 turbo overdrive.pclr?dl=0

-

So I have my open loop control pretty much sport on but the closed loop isn't quite there. I am unsure what needs to be altered. I have it where it doesn't overshoot but it does hit target and oscillate nearly 20 kpa.

Any suggestions?

https://www.dropbox.com/s/55qq89yp0esygd7/6.1%20pass.llg?dl=0

https://www.dropbox.com/s/bui52a6m6188gjy/Ford%20363plus%20ve%20smooth.pclr?dl=0

-

Thanks Adam. I figured that was possible for a single bump. Any ability to do a creep option?

I have a standalone bump box (simple stage) that has a lot of adjustability however when taking it down to a reasonable amount of bump harshness i have to hit the button several times to move just a few inches so i was hoping to be able to get a creep/super fast multiple trigger even if I have to make the Link extreme feed into the simple stage.

-

Would there be much interest in adding specific functionality of a trans brake bump/creep? I understand there probably isn't nearly the drag racer following here compared to other platforms like Holley or Megasquirt.

I figure I could build my own with a SSR and a GP PWM output setting my own parameters but it would be nice to have along with the launch control setup.

-

Here I was able to compress it and a drop box link if the .rar isn't good.

https://www.dropbox.com/s/vlrfkguu36xsjkd/drag run.llg?dl=0

-

Thanks. I will shift the retard start point higher. The converter is flashing to 5800 as soon as I release the trans brake so I am not thinking that's the issue.

-

I searched a bit and didn't see many questions asked about trans brake boost building setups.

I have a turbo v8 with a 2 speed powerglide. I am using Launch Control settings as a 2 step which works but I can't seem to get the RPM I desire. I have it setup for 4000 rpm with a control range of 200 hoping to see 3600-3800 on the brake but I am only getting 3200 creeping to 3400 as I hit 6-8 psi of boost. Not sure if I am pulling too much timing too soon, if my overall settings are incorrect or if its a complication because I am using DBW. I did notice one of the logs the TPS was moving a bit but I didn't look at APPS to see if it matched or not. The log never shows launch limit as active.

Is launch control the right item to use or should I be using anti-lag for this? I came from a Megasquirt ecu and it had Launch Control as well as a separate 2 step feature for what I am trying to do and it hit the mark right off the bat.

Here is the tune. I can't upload the log as its 700kb+. Can I compress it or save a smaller section of it?

-

1 hour ago, Adamw said:

What have you got for P & I gains in that run? One of them is too high, Im leaning towards too much I.

I is the same as the original log/tune file above.

I only changed the stage 3 to 10kpa, added some D and lowered target from 220 to 210ish kpa.

I was much more active this time so I will try lowering.

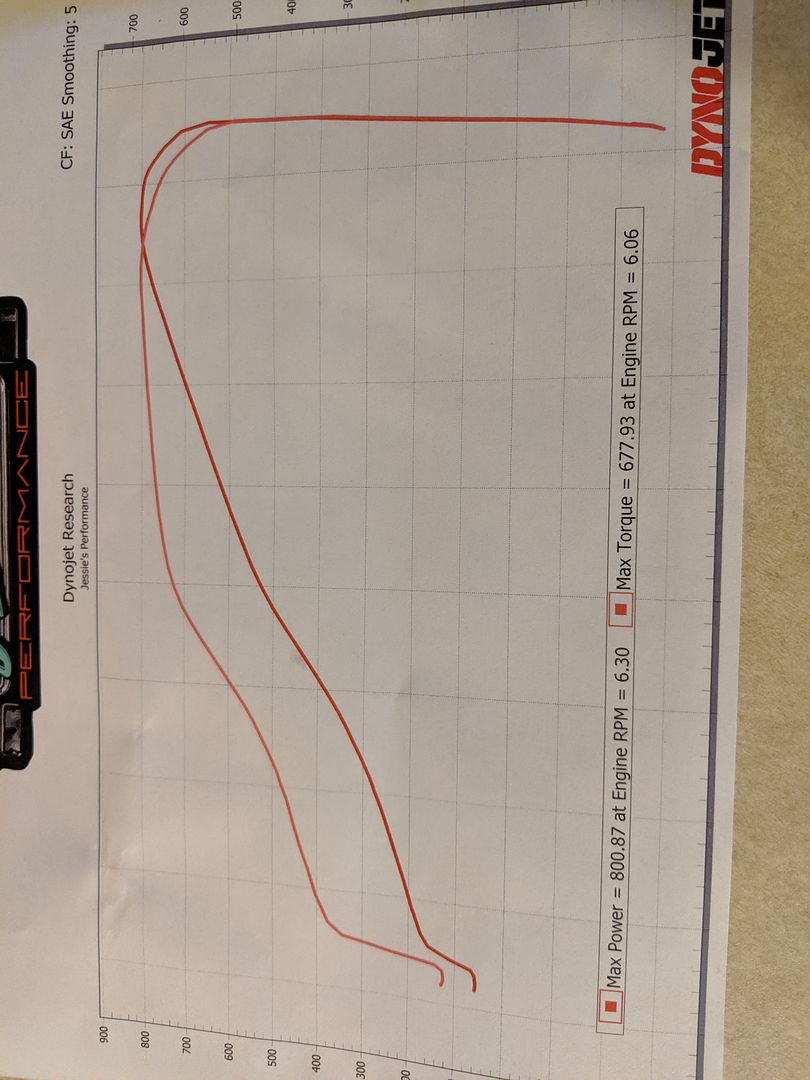

All in all this was so much better than before and stayed within 1-2 psi of target. This netted my fastest 1/8 mile pass to date and on less boost.

-

On 3/10/2019 at 11:09 AM, Tim D said:

In open loop the boost is solid at 17 psi. Just a lot slower getting up to peak.

So i did what Adam suggested and its much much better. Doesn't overshoot like it was but does oscillate from 205-211 kpa throughout a pull and is enough it makes the rpm fluctuate a bit.

Ignore the stupid high IAT...forgot to activate my meth injection system.

-

Can someone look over this log file and included map and suggest some PID changes to stop the boost target overshoot?

I can see them all working in the log - Integral steps on and starts reducing duty but it plateaus right when target is achieved and doesn't stop the overshoot.

-

Thanks all.

This is perfect. I didn't have a ecu read fuel pressure until this week - just a dash gauge. I run staged dual walbro 450 pumps and had an incident last week where a ground wire was pulled loose and well..one 450 is only good for about 660 whp on e85 as I found out on the dyno. The operator got out of the throttle when lambda reached .906 at 6500 rpm and 13 psi. Its impossible to watch everything all the time so I wanted a built in safety for just this reason. I always know if my main pump is working since the motor won't run otherwise but the staged pump is a crap shoot. I will set it up as a map limit instead of rpm. My base pressure is 300 kps but it idles at 255 because I have decent vacuum and on decel it can get as low as 220kpa so I would be afraid an rpm limit might be harder on the motor but I could be wrong.

Thanks again!

One more question though..

My "fuel system" was setup as map referenced before today. If I change to FP Sensor will that alter my ve table fueling any? (provided things were setup correctly before)

-

Is there a way to setup a safety around fuel pressure? I would like to have a safety that says if fuel pressure drops during wot acceleration i would experience an ignition cut or reduced boost. Possible?

-

I get what you are saying now about the APS vs load, so I will certainly abandon that idea and focus on the tps load resolution on the AE tables.

As far as tps% it's a GM LS7 throttle body that's around 90mm feeding a 363" v8. Idle advance is 23° btdc. The throttle body is supplying all of the idle airflow and generally the lowest I see is around 14% and when cold around 18% to.

The VE table is pretty spot on and uses very little cll correction, usually less than 3% in basically all driving speeds/loads but yes in throttle transitions there are very brief lean spikes and while tuning for this is when I paid closer attention to the clamp and rate tables and noticed my driving tps% was at or beyond the default taper settings. I will just play with sliding the taper over a bit to see if that helps. The AE is doing exactly what the tables are telling them to do so I just need to adjust accordingly.

-

So I was out doing a little AE tuning tonight after watching some of the Evans Performance videos. After I was watching the logs as setup in their video and since I am DBW and it's giving all the idle air, the idle tps is 16-19% and cruising at hwy speeds is 32-36%. The typical AE tables give more fuel enrichment, clamp, etc at lower % and less as tps increases. So I was wondering if I should swap the tps axis for APS to gain that resolution back. Would that be fine to do? Any issues that I am not thinking of?

-

FYI I installed the simple stage bump box and all the issues went away.

-

Well it's set to Always On with a disarming speed of 35 mph. I would assume it will always be active below 35 mph based on those settings.

I would make the TP low be above 0%, like maybe 10%.

Link Extreme on a Barra swap

in G4+

Posted

How is the cam trigger setup them with the 4 uneven posts? I would gladly run that, I just assumed it would be problematic.

I am using the factory 36-1 crank wheel but with a Hall sensor.