MagicMike

-

Posts

162 -

Joined

-

Last visited

-

Days Won

6

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by MagicMike

-

-

The 3rd condition, you select DI as 'on', and then the next selection is the DI 'number', in this case (Jay's example), 1.

-

Oh well, thanks for the reply

-

Just did a search for SSI-4 and found this thread.

I have an Innovate SSI-4 that I purchased to use with the Adaptronic ECU I had previously. Never used it, not really worth my time/loss to sell it.

Can it be put to any use whatsoever with the G4+ plug in I have?

-

Cool thanks mate. All this is purely theory for me at the moment. Have not yet connected the ECU to the car.

-

So I have another question about the flex sensor. I have read the info about wiring it in to a DI (1-8) etc. So I was looking at what is spare in the 300z basemap. Turned on DI5 and allocated ethanol sensor. Then I happened to notice the 'Ethanol Sensor' listed at the bottom of the DI list. Is this some kind of preconfigured input? If so, where do I wire my sensor if not (one of) DI5 to DI8 on the expansion looms?

-

Thanks again for all the info Adam. Screens attached of help and software menus regarding FP cont etc. Assume they have just been mixed up somewhere along the line?

Is it possible to know if there are any conditions etc applicable to any of these 4 being active? Only asking as the factory pump control does the prime etc.

-

Hi all,

I am in the process of mapping out what I need to wire in to where for my application (Z32 with plug in g4+). While I do have 2 XS looms which should be enough for me, I am also trying to establish what factory pinouts are used, which ones are not used, and which ones are configurable.

I have aligned the info in the link manual (and the descriptions provided in the software for the 300z basemap) with the factory pin functions, but there are some gaps I think. I have attached the lot, but mainly interested in these: EGR, AIV, FICD, PRVR. The ones below are not mentioned (and aren't plainly obvious like grounds/powers etc).

PIN

Link Manual/Help

Desc from Link Basemap/Software or Nissan Data

47

Check Signal on Diagnostic

22

Diagnostics Send Data

21

Diagnostics Receive Data

8

AIV control solenoid valve

5

Signal to Automatic Transmission

102

EGR

56

Signal to Automatic Transmission

54

Throttle Valve Switch (idle position)

40

Signal to Automatic Transmission

37

AFM Orange Wire (Not Used)

33

F.I.C.D. Solenoid Valve (fast Idle control)

31

Diagnostic Clock

16

ECCS Relay Coil Ground

15

Signal to Automatic Transmission

14

Signal to Automatic Transmission

115

Oxygen Sensor Heater

111

PRVR

What does the ecu do with these? Can I get control of them?

Next, Aux - Inj 8 is tagged against 2 ECU PIN's, 19 and 6. Nissan says that 19 is the Rad Fan Relay and 6 is Rad Fan Sub Relay. Assume I have removed my fan and would like to use this driver for something else, which pin would I use?

Next, I am interested in the fuel pump controls.

PIN

Link Manual/Help

Desc from Link Basemap/Software or Nissan Data

???

4

Aux - Inj 7

Fuel Pump

Nissan says this is AAC valve

104

Aux 2

FP Control 1

35

Aux 5

FP Control 2

Nissan says FPCU

18

Aux 6

ISC Solenoid

Nissan says Fuel Pump Relay

Interestingly, Nissan says that PIN 4 is the AAC Valve? FPCU, PIN 18 is the fuel pump relay (Link says ISC Solenoid???) Have these been mixed up somewhere?

PIN 35 and PIN 104 are for the FPCU.

With my fuel setup, I have the FPCU replaced with a relay (still triggered by ECU) to control the in tank pump (full time full speed). I have my big external powered with direct battery power via a relay off the same signal as the in tank, but the pump has another speed control by PWM. I assume I can use either PIN 35 or 104 for this? Looking at some kind of PWM by injector duty relationship.

Finally, silly question (if the others weren’t also). What is the function difference between a temp input and a volt input?

-

I had to source a donor ecu to use for the case. Luckily a mate recently sold his GTR as a shell so I got his Mine's ecu cheap enough to bin its guts. Only last night installed the link and XS looms.

Ross balancer and Cherry sensor are installed. I pretty much just have to finish the wiring for all the other inputs and then hopefully try and fire it up (or at least be able to crank it and check the triggers).

-

Not being able to adjust pressure down lower than 3 bar isnt ideal, I can drop mine to nearly nothing. But factory askes for 3bar without manifold reference, so it is on spec.

-

ENGINE

Block bored 20 thou oversize, decked and o ringed, fitted with forged ACL race pistons and rings

Scat H beam conrods, fitted with ACL race bearings

Crankshaft linished and deflashed oilways

Modified oil pump for greater flow

Heads have received a lot of work with machining, porting and polishing, cc’d, flow tested

1mm oversize Ferrea valves

Competition valve springs

Compression set at 8.5-1.

Inlet manifold has been match ported to the heads and the upper plenum

Modified crankcase ventilation with catch can

(Jim Wolf Technology) JWT 400+ wild Cams

BDE (Brett Dempsy Engineering) modified Intake Cam gears

Tomei adjustable exhaust cam gears

A new set of hydraulic lifters fitted with shims has the motor running nice and quiet

2 x GTX 28/63 turbos

Complete 2.5in intake to turbo to intercooler to throttle body piping upgrade

Massive 2.5 inch, ducted side mount intercoolers

54mm throttle bodies with match ported plenum

Twin Apexi power air filters

Turbosmart, BOV’s

Ross Metal Jacket balancer (36-2 wheel)

56mm Alloy Radiator

72 plate external oil cooler

Z Center upper timing belt cover

ECU Link G4+ 300z plug in

Wiring Specialties wiring harness

EXHAUST

Custom 5 bolt, divorced dump pipes

Mike Smith Performance exhaust manifolds

Twin 3” system through hi flow cats, and pair of Varex adjustable Mufflers

FUEL/IGNITION SYSTEM

BDE (Brett Dempsy Engineering) top feed fuel rails with various modified stock bits to suit (balance tube etc etc)

Bosch 1650 top feeds

Fuelab 52901 regulator

Walbro 460 in tank

Custom surge tank

Fuelab 42401 external pump

Custom fuel cooler

Teflon braided lines front to back with various heat shielding

Multiple fuel filters, pre external pump, pre fuel rails, post fuel cooler (pre main tank)

Flex sensor

Battery has been moved to the boot area sealed in a battery box fitted with an isolation switch

Series two power transistor unit

HKS DLI Ignition Amplifier

Spitfire coilpacks

Engine earthing kit

DRIVELINE

OS Giken twin plate/lightweight fly combo

Chrome molly one piece tailshaft.

Richmond leader diff gears of 4.11 ratio

SUSPENSION

Bilstein PSS9’s coilovers

Powertrix front upper control arms

Powertrix front lower tension rods

Tune Agent rear camber

Tune Agent traction arms

Energy suspension bushings all round

Nagisa Auto Gacchiri Support fender braces

UAS HICAS lock out

BRAKES

Front - Stop Tech ST-40 calipers big brake kit

332 mm slotted, curved vein rotors

Braided stainless brake lines

Ferodo 2500 pads

Rear - Reliance Edge 297mm slotted rotors

Ferodo pads

Stone shields have been removed and tubular ducting has been fitted for extra cooling

WHEELS and TYRES

18x9 and 18x10 Gram Lights 57F-Pro

Also available is a pair of stock 16” wheels fitted with Mickey Thompson ET street radials for those nights at the drag strip

EXTERIOR

2000 model urethane front bar with Powertrix carbon air guides

Twinz Design front lip V2

Various undertrays

2000 model rear tail lights

Modified stock bonnet

Modified nose panel

Genuine Trust/Greddy side skirts

UAS rear wing

UAS enclosed rear bar fitted with Perspex diffusers.

Aero mirrors

Custom made air guide for improved cooling to the radiator.

HID headlights

INTERIOR

Recaro SR3 driver and passenger seats on Z32 recaro rails

Stock gauges have been replaced with el panels giving various shades of blue

Genuine Defi triple set, oil, water temp and pressure

Pivot boost gauge

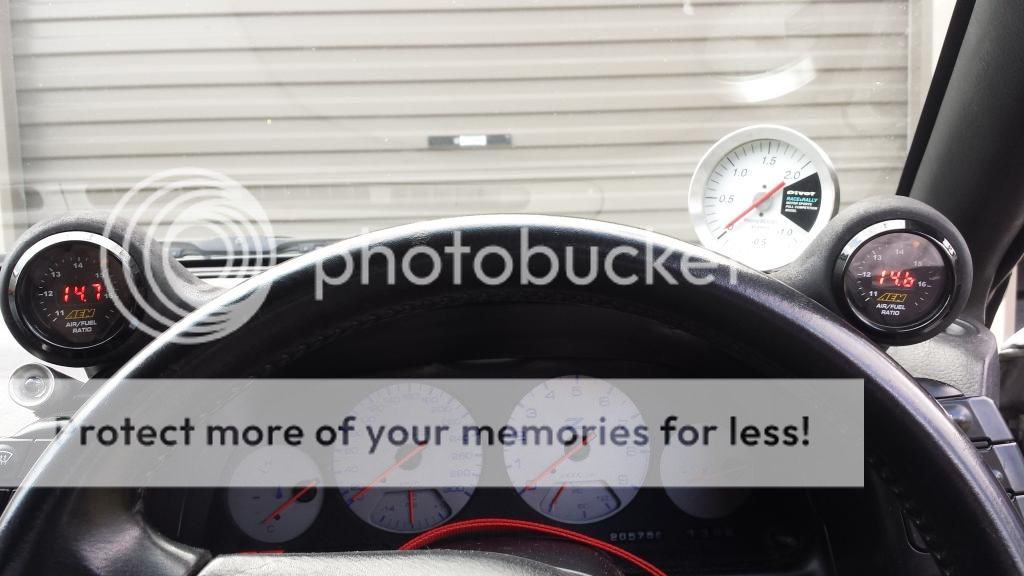

Twin AEM wideband AFR gauges

Boarder racing gauge hood

Kenwood head unit with four kenwood 5” speakers

Terrano chrome door handles

Leather 300zx logo handbrake boot

Leather 300zx logo shift boot

2000 model gear knob

Leather trimmed doorcards, glovebox, center console etc

Can has previously made 616hp @24psi on pump fuel. This was pre fuel system upgrade with Nistune. Car has gone 11.3 @ 120something, when it had about 500rwhp.

Current work in progress is setting up the crank trigger system. I have the crank sensor mounted, and I have just modified the CAS for the cam pickup last night (aluminium tape over the optical slots). Still haven't decided exactly how to attack the cam sync, but figured this is a good, cheap start.

I had previously got all the wiring in order for an adaptronic ECU, but since sold that (never used) in favour of the link. So I have to have another look at all the wiring for all the extra sensors again. Also have a fancy Specialty Z sump to go in at some stage when I could be assed.

Then it should be nearly ready for start up again.

G4+ plug in - 300Z questions

in G4+

Posted

So got this fired up on the weekend, which was great. I have a couple of questions now. The attached trigger scope, normal looking? Seems pretty uniform, just the little variations at top and bottom of some that I am asking about. If not normal, possible causes? I have not tried adjusting the crank sensor placement and/orientation yet. Using a Cherry Hall sensor, and modified Cas for sync. I have circled some of the bits I am asking about in the screenshot.

Next question is around fuel pumps again. I have Inj7 set as function 'Fuel Pump' and wired to trigger OEM FP Relay, whose output in turn triggers 2 relays (one for each pump) that give battery power to both in tank lift pump and external large fuelab pump. I have Aux 2 wired to the speed control input on the big external pump.

I am seeking clarification on the fuel pump control settings, and which settings relate to which outputs.

Is Inj7 prime, then on where engine speed > 0, and all the other options there relate to Aux 2 only?

Trigger Scope Log 2017-04-25 11;42;33 am.llg