-

Posts

488 -

Joined

-

Last visited

-

Days Won

33

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by Ducie54

-

-

Since you are running a fuel pressure sensor i would be setting your base fuel pressure by looking at your differential fuel pressure at idle once every thing has come up to temp. This way you don't need to take the vacuum hose off the FPR. Also are you running the fuel pumps off the std wiring or a another relay closer to the fuel pump

Other things to look at is the ID of the fittings and line going to the fuel pressure regulator. Some brands of fittings have a smaller ID even tho the OD is what your after. Here is a link to Injector dynamics fuel delivery PRI videos that may help, there is 9 to watch. https://www.youtube.com/user/InjectorDynamicsTV/search?query=Fuel+Delivery

-

From what i can see your differential fuel pressure drops and your running out of injector flow because of it. I would check your fuel pump flow and voltage to the pump.

-

I've been using some dual Emtron CAN widebands. Can't fault them so far.

-

Do you have any pics of your setup? Curious to see how you have setup the slushee evaporator.

In my water tank I added another tank inside to fill with dry ice. I also have IAT sensors both side of the water core to measure temp drop across the core.

The more water flow you have the better I found.

-

I just use a Honeywell sensor. With the T1 race canister and brake hose in a few loops. No issues over the last few years running.

-

Sorry I don't know but curios to know what would require this sort of setup?

-

Without a log I cant see whats happening, helps if all parameters are logged that a relevant to the issue. Others might be able to help there. The spike to 12,000 rpm looks trigger related.

When i configured a rpm limit i use lower rpm like 4000rpm to make sure it works first.

-

When i open the log it was full of start stop lines. Makes it hard to read.

-

-

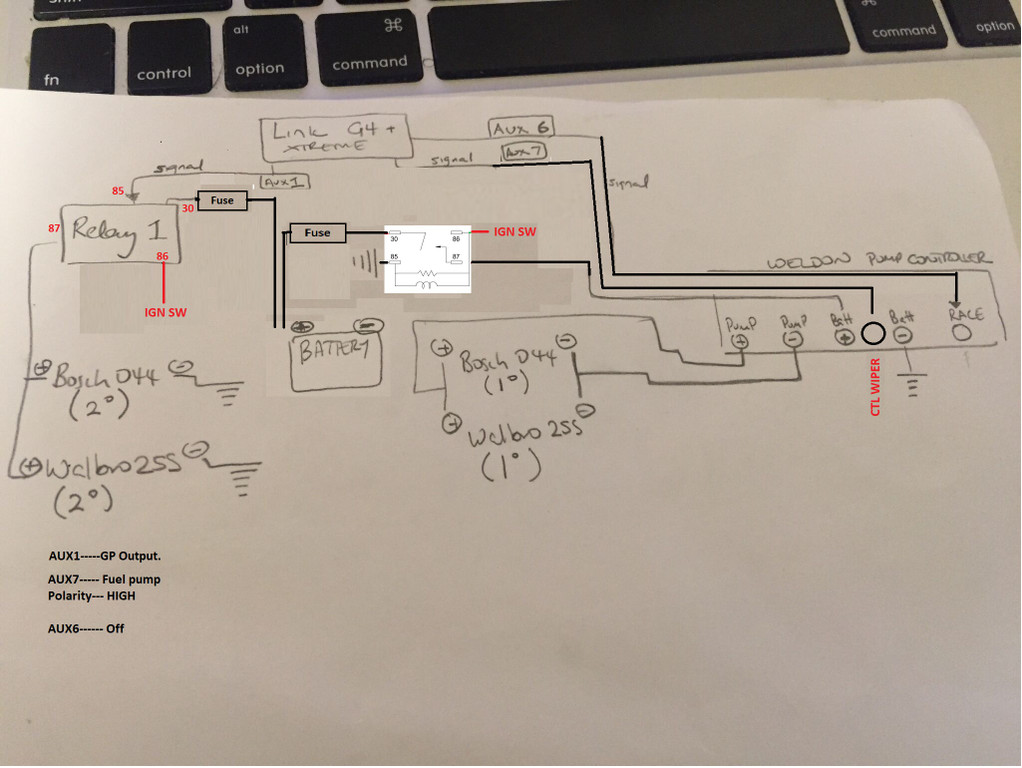

You need to draw a diagram on how the fuel pumps are setup and another on how the wiring is done. I think there is a lot of confusion here. Also post a pic of the Weldon wiring diagram. I cant find one online that i can read.

I have a funny feeling that the Weldon fuel pump needs to see a POSITIVE to activate. I recommend you start by running the fuel pump speed control method to OFF until you know all pumps work as expected.

-

Be careful as I've seen some liquid filled gauges read differently when the gauge gets hot.

Do a log with differential fuel pressure not just fuel pressure.

-

Have you compared it to a mechanical gauge?

-

You also need to swap the output units from lambda to afr.

-

The last firmware had 3D negative/positive trim tables.

-

6 hours ago, a6_quattro said:

I'm starting to get really anoid of the total silence from the Link team. it would be decent if youcould give me some hint when in time you have the new release planned?

Just give me a hint and I consider if a change of brand is nescessary because this has taken far to long time to fix. Other brands seems to be more "on their toes" so I'm not going to waste time waiting for something that never going to happens and promised when purchasing the product.

/Hans

Ive had nothing but good experience with all the tech guys. As for firmware updates the last one before it was pulled I had no issues with it. In regards to the closed loop e throttle problem you have had did you ever end up answering Adam in his last post?

-

Whats wrong with using an overlay table?

-

Turn overrun fuel cut off. Then add fuel to the area of the map in decel.

-

Are you running a fuel rail pulse dampner? Injector dynamics have a good utube video about them. Also how long is the vacuum line to your fuel pressure regulator.

-

A log and a copy of your map will help with diagnoses.

-

1 hour ago, Zchris said:

Adam, I was using manual mode. It started tuning without hitting F10. I used F10 to set the cell when the green light came on. I did those initial cells unloaded off the dyno. As soon as I put any load on it on the dyno, like just trying to get the wheels rolling the AFR goes to 22.7. Any suggestions?

You need to tune EACH cell. The fuel table graph looks like it hasn't been touched

-

How have you done the wiring between the CDI and the coils? Have you followed the M&W manual?

I'm running M&W CDI with denso coil on plug and have no issues with the battery being at the back of the car. Just earthing battery to body but I guess not all boddies are the same.

-

Watch your IAT on a hot restart. If the temp sensor gets heat soak the ecu in modelled mode will pull out fuel. Add fuel to the high temp no throttle area of the iat correction table.

-

-

Yeah very strange that one.

I reckon this hasn't seen a dyno or a knock listening device.

ECU constantly earthing injector 1 driver. GTRLink

in G4+

Posted

Have a look to make sure the injector test function is not on.