-

Posts

488 -

Joined

-

Last visited

-

Days Won

33

Content Type

Profiles

Forums

Events

Gallery

Blogs

Posts posted by Ducie54

-

-

As a feature request can we have the option on which Lambda sensor is used for CLL.

As example I'm using 5 lambda sensors. One in the turbo dump pipe and 4 in the turbo manifold using a CAN module. The software uses a average for CLL but would be nice to use Lambda one so manifold pressure is not an influence. Currently to get around this from happening I've set the 4 CAN lambdas as CAN TC.

-

-

Too high of a dead time can have the same issue. Do you have the correct injector data.

-

These are the settings from a MR2 file i have. Hope that helps

-

Are you getting fuel flow and pressure?

Any idea the condition of your fuel filter.

-

alt F4

-

11 deg retard sounds a bit extreme how much piston to valve clearance do you have?. If it was me i would set them both to 0 and see how that effects things.

-

If this is a new install did you unlock the ECU.

-

5 hours ago, cj.surr said:

Think about your statement. You would rather the engine overboost than have a mis-shift? Forget the cause of the overboost, It could be caused by software or hardware.

There is a reason LINK has a shift cut prioritized over other cuts. As others have mentioned a tunner should build into his map a safe guard to reduce boost, ignition and increase fuel in the area of the MAP were damage could occur if reached.

IMO a MAP cut should only be reached if the wastegate line falls off.

Stop being so defensive and take advice, no one wants to hear about members spending money or time on things that can be fixed. There's a handful of software changes I love to happen, but know it never will and I just have to learn to work around that.

I'm sure if you asked several guys would be happy to help if your not interested so be it.

While I'm far from a pro tuner I still know the basics and spend a fair amount of my free time helping members fixed there payed tunes. I got better things to do than troll on fourms, getting too old for that Shit.

-

Again please reread, rpm and map limit don't work together as shown by my example. As I said and again by LINK. Your poor rpm limit caused the MAP to increase. Again shown by the log.

What ECU brand has MAP limit working with shift active? I'm a tuner and would rather shift cut before map limit. Miss shift can't be undone, a shitty tune can.

-

35 minutes ago, Stevieturbo said:

Perhaps get back into the real world and use some common sense.

Why should you need to anticipate basic tuning for cells ? Seriously, think about what you're saying.

And BS about the "lean firing that comes with fuel cut"

Glad I'm not the only one thinking the same thing. 20 times the statistics show it has hit MAP limit, you would of hoped the tuner worked it out before it blew.

Trying so so hard not to pick this to threads.

-

Instead of getting defensive, I would be asking for help to stop it happening again. Plenty of ways to do this.

-

So your topic should be why does Rpm limit lock out map limit.

Agreed should be nice if both worked simultaneously but a RPM cut shouldn't build boost if setup correctly.

HPA do some good webinars on boost control and setting limits.

-

21 minutes ago, cj.surr said:

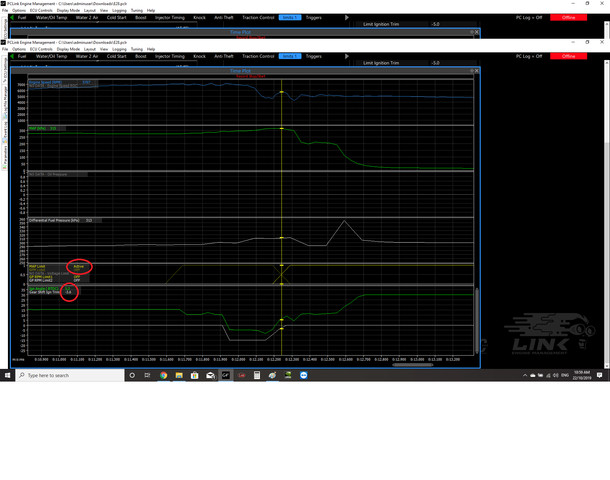

When I look at the log, I see MAP limit being activated at 22.18s. At 22.03s, my MAP is over the limit at 303kpa and rising. The hard limit is set to 100% igntion cut and the hard limit delta is set at 3kpa. MAP limit at this point is somewhere between 290 and 300kpa. 100% ignition cut did NOT engage and MAP limit did not pull timing.

Again Map and Rpm limit will not activate at once you can see that in the log file. RPM limit starts @ 21.581 and finish's at 21.181 MAP limit starts at 21.181ms at 315 kpa. Soft cut kicks in timing goes from 8.9 to 4.3 @22.232ms 297Kpa @ 22.271 MAP is now at 213Kpa and outside Hard cut range.

36 minutes ago, cj.surr said:I don't understand why you're being argumentative. I completely understand that the RPM limit settings were too aggressive. Your suggestion about the DC% table is honestly ridiculous because the engine should have a 100% ignition cut INSTANTLY if it ever passes the MAP limit + 3 kpa. The ECU should never need to be pulling a DC% from there. The wastegate would not act fast enough to save the engine anyway. And you can completely forget about that helping in a wastegate failure scenario.... It's a hack and incomplete way to prevent an overboost.

Im argumentative as your topic says (Map Limit didn't engage during Shift Cut) Which is false and the above screen shot show it was engaged, your blaming that as to the reason of the damage. My suggestion come from the theory of HPA academy and works well when boost is over target. BUT cutting fuel and ignition will also be best for setting a limit.

44 minutes ago, cj.surr said:It's clear that the hard limit on boost cut did not come in when it should have because it was during a shift cut (partial cut). What I want is an answer from the developers why it was programmed this way and if this can be changed.

No it didn't come into effect as you were still in RPM cut. By the time it switched from RPM to MAP limit and applied soft cut it was UNDER the MAP hard cut threshold. The help file shows a 3D pic of how the advance mode works.

-

I was trying put it nicely that you did a poor job on setting you limits. MAP limit WAS engaged during shift cut it pulled 3.6 Deg out it just wont do both MAP and RPM at ONCE.

Why don't you set the RPM cut so it doesn't create a Boost over spike?

And this is why the wastegate DC% table is so important, why do you have a target DC of 48% @ 300kpa if your limit is 290KPA?

-

Boost cut cant engage @293KPA as you were already in RPM cut. Once RPM cut dropped out MAP Limit was activated.

The trend shows boost raises when ignition starts being pulled from rpm cut then more again from shift cut. One point during your cut ignition angle is @ -5 deg while at 100% throttle Still with fuel being sprayed.

-

After another look it looks like your MAP limit cut is set up like the RPM limit cut. So when you hit RPM cut the boost pressure goes up how do you expect the MAP limit to DROP boost? I would take it back to the tuner and ask why this hasn't been tested. I would also add more resolution in your boost target table at the MAP limit. So when it gets close to MAP limit the DC% drops. EG set 295kpa row several % lower than the 290 row, set the 300 kpa to ZERO. That way your not relying on PID to reduce DC% when @ MAP limit.

-

So when you first configured your RPM limit did your boost pressure still rise? I wouldn't be using Ignition cut on a turbo Engine but that's me as your still pumping fuel into a hot turbo manifold.

Also you AFR is not even close to tracking the target?

-

-

I agree with Adam on this one. I've run injectors at high pressure for ages on a test rig and the increase is bugger all. I found insulating the fuel rails and lines in the engine bay give more of result than slowing down fuel flow. I'm even running phenolic fuel rail spacers to help.

What suit of fuel temps are you seeing?

-

I cant see how idle ignition couldn't pull that rpm back down during that one specific time.

-

CamB as you know I've done this testing also. I weighed the fuel as it was easier to do the testing. Just have to make sure you spray into a big container with a larger exhaust filter to stop spray back. Next time I do testing I will measure the weight of the fuel in the test rig before and after testing not the amount sprayed.

To measure max Cc I used a aux output.

Also there can be a big difference in SPAT of several injectors. I'm running wideband in each turbo runner and the accuracy and repeatability of the injector in the lower IDC is just crazy. Even using ID objectors.

Even with all the injector data supplied by ID I still needed to tweak there dead times. Reason being running large injectors in non linear range at idle and low loads.

Get yourself an external power supply to run just the ECU and injectors. I think mine is a 30 amp only because I wanted to run a pump as well.

-

Yes there is a function based on AFR.

-

Would using TEST ON work? This should be a constant on anytime the ECU is powered up.

G4x Base map

in G4x

Posted

Is it possible to have a Math block drop down box with the maths all ready worked out?